Flow Nozzle Straight Run Requirements

Flow Nozzle Straight Run Requirements, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

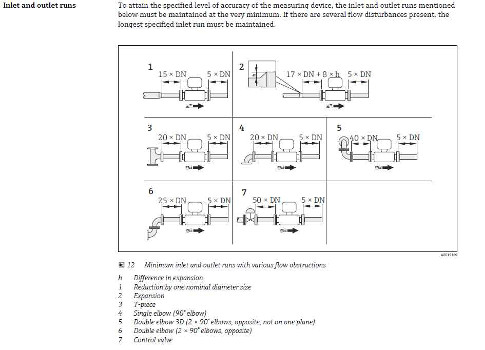

Shorter straight run lengths are possible but accuracy will be affected.

Nozzle gun orange. 25 straight run requirements to obtain published accuracy sufficient straight run is required to produce a fully developed flow profile. However the same flowmeter may require 30 diameters of upstream straight run to measure accurately downstream of two elbows out of plane a configuration that tends to generate more velocity profile distortion. Siemens sitrans fup1010 portable liquid ultrasonic flowmeter.

Flow meter piping requirements diameters of straight pipe required for various types of fl ow meters diameter d nominal pipe size example. But a partially open valve upstream of the meter will require 25x the piping diameter and multiple disruptions such as a spiral or consecutive elbows can require 50x the piping diameter. When the orifice to pipe diameter ratio b is 08 i use 50 for reducers and throttling valves and 40 for elbows in two planes but spink for example recomends 60 to 100.

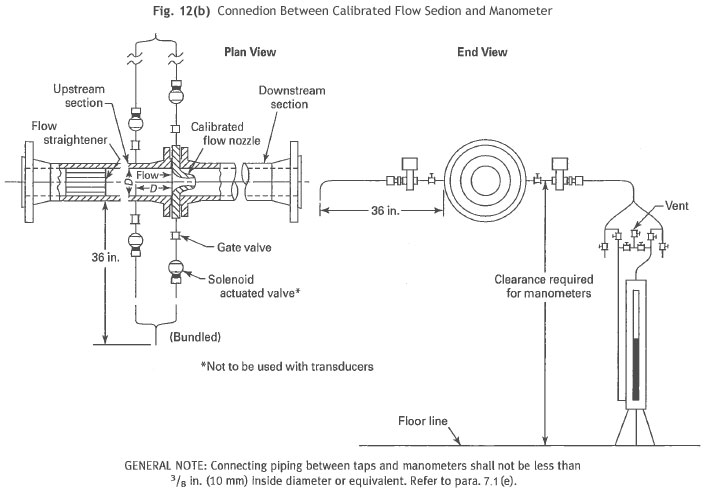

The mounting flange is sandwiched between the end users pipe flanges to hold and seal the flow nozzle inside of the process piping. Additional straight lengths may be required per the standard as defined by the disturbances upstream of the flow nozzle. The lengths are measured from the inlet plane of the flow nozzle.

Consult the factory for further information. The mounting flange can be provided with a raised gasket face or rtj groove as required. Whenever possible the profile for the high beta ratio type is selected so that the ellipse terminates within the pipe inner diameter.

The flow nozzle fn is a long radius type with wall taps sometimes called radius taps or d and d2 taps. In general downstream straight run requirements for turbine flow meters are around 5 10x the piping diameter. The straight run recommendations vary widely.

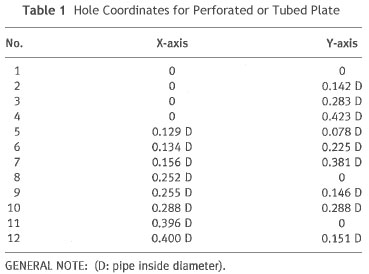

13 diameters of 6 pipe 78 13 diameters of 10 pipe 130 beta bore idpipe id bore is the smallest diameter of an orifi ce or nozzle up upstream diameters down downstream diameters. Minimum recommended straight pipe length. As a pd type flowmeter straight pipe length doesnt significantly impact meter performance.

Minimum straight run requirements upstream and downstream of orifice plates as determined by bela liptak. Ideal for quickly checking liquid flow in pipes when other more permanent solutions arent typically necessary or are unavailable.