Flow Nozzle Tapping Orientation

Flow Nozzle Tapping Orientation, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

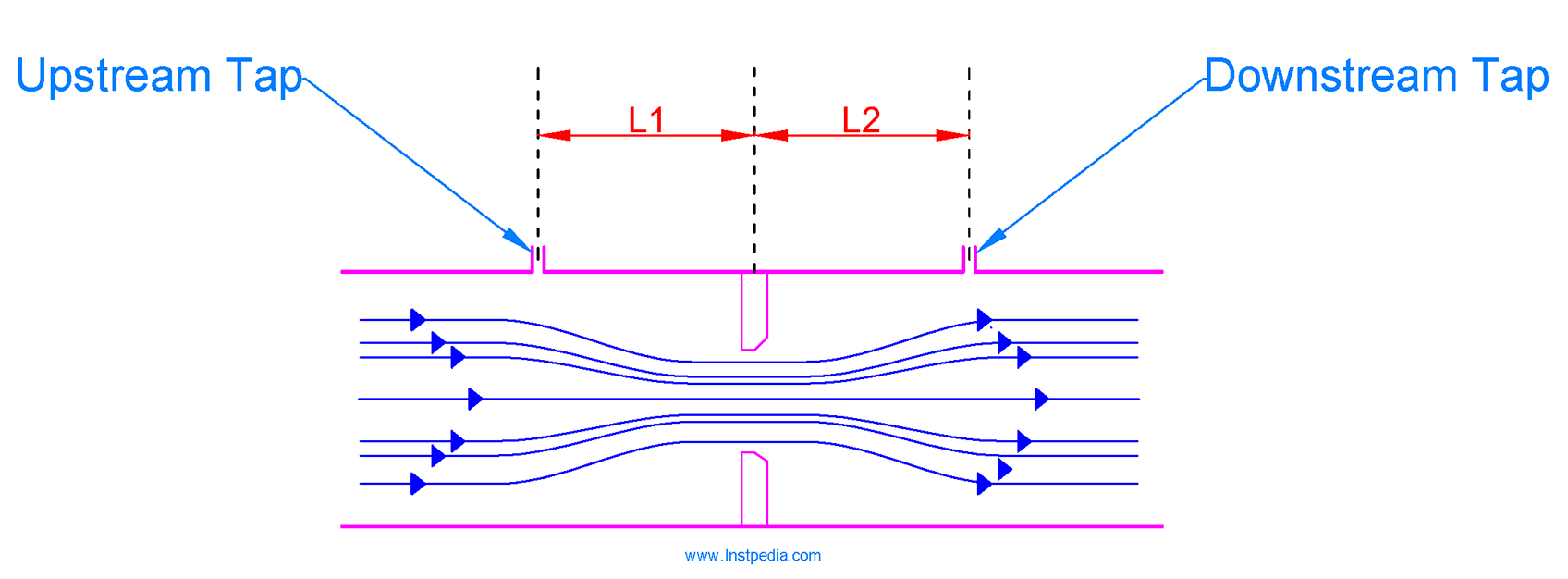

Ideally the upstream pressure tap will detect fluid pressure at a point of minimum velocity and the downstream tap will detect pressure at the vena contracta maximum velocity.

Brass nozzle deutsch. The flow nozzles area is minimum at its throat. Openings are provided at two places 1 and 2 for attaching a differential pressure sensor u tube manometer differential pressure gauge etc as show in the diagram. Whenever possible choose a horizontal pipe for sampling process gas.

Tapping a gas stream. The flow nozzle lies between the orifice plate and the venturimeter both in performance and cost. The difference in the static head pressure can be compensated using the zero adjustment on the pressure transmitter.

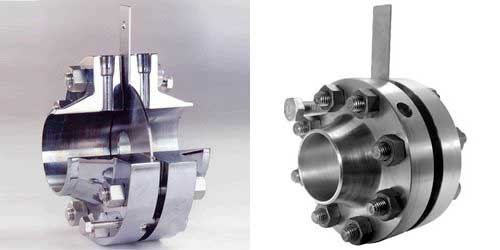

In gas service the taps should be oriented so the impulse tubing remains completely filled with gas while ensuring there is no accumulation of liquid between the taps and the transmitter. For 585 main steam line use liquid a nd steam horizontal orientation for mounting recommendations. A flow nozzle which is held between flanges of pipe carrying the fluid whose flow rate is being measured.

On the bottom of the pipe. Its also easier to find a long straight run. Consideration for orientation of this nozzle is the same as the inlet nozzle.

Orifice plate flange taps orientation fluid going down. 2 this mounting orientation is not recommended for the annubar type l main steam line. Tapping a gas stream whenever possible choose a horizontal pipe for sampling process gas.

The horizontal orientation allows the nozzle to be vertical. Consideration for tank draw off nozzle for storage tanks in hydrocarbon services to permit periodic draw off of water which normally collects in the product an api low type shell nozzle and a drain valve are normally provided at the bottom of the tank. Orifice plate flange taps orientation fluid going up in the case of having a descending fluid the impulse piping must be configured as shown below.

The horizontal orientation allows the nozzle to be vertical. Its also easier to find a long straight run. At points a and b.

An overview of the most popular tap locations for orifice plates is shown in the following. Facing these constraints you can weld a valve onto the nipple or use a flanged pipe nozzle instead. Locate the nozzle on top of the line figure 3 so any dirt or liquid falls back into the process pipe.

1 the flowmeter orientation recommendations may vary for the gear drive flo tap annubar type. A typical section through a flow nozzle is shown in figure 494 where pressure tappings are located immediately adjacent to the upstream and downstream faces of the nozzle ie.