Nozzle Definition 3d Printer

Nozzle Definition 3d Printer, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Nozzles are categorized in several ways.

Turbo nozzle rebuild kit. The standard 3d printer nozzle material and most likely the nozzle type that came on any desktop 3d printer you bought recently. Some brands have preferred shapes. When it comes to dialing in your 3d printer the nozzle is often overlooked.

As the last part to be in contact with filament the nozzle can influence strength print time and print material. Once the types of nozzles have been clarified one must take into account a very important parameter of the 3d printing configuration that is affected by this component such as the layer height. 3d printing with fuse deposition modeling is already a slow process but it takes ages when you are using a smaller nozzle.

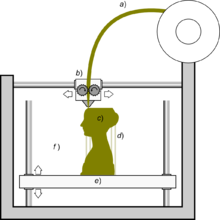

Here we take an in depth look into 3d printer nozzle size and material. To begin we must know that the recommended maximum value. The nozzle is the component of a 3d printer that deposits the molten filament into the build area.

Standard brass nozzles are great for general purpose 3d printing but abrasive filament like nylonx requires a high performance nozzle. The reason for this quite simply is thats its a great all rounder nozzle size. An important part of desktop fdm printers is the nozzle.

Some of the most important factors to consider when choosing a nozzle are the size material and shape of the nozzle. This parameter is key to achieve the correct combination between finish and duration of 3d printing. Of the 3d printer nozzle materials it is the softest around.

There are many different types of 3d printer nozzles available and leveraging their different strengths is important. Printing the 22x12 mm owl shown above took me more than half an hour while trying to achieve the best quality. This means you can print exceptional detail and it wont take forever.

The bad how slow. Nozzle shapes and nozzle materials obviously the nozzle diameter is one of the major parameters when 3d printing. The most common standard nozzle sizes are the 04mm or 035mm nozzle used by most current 3d printer manufactures currently available.

Hardened steel stainless steel and brass. Here are the best tips and tutorials for 3d printer nozzle cleaning. Nozzles are the last physical item in your printer to touch the filament before it becomes your 3d printed part so its important to understand how they work if you want to take full advantage of the possibilities afforded by the different types.

Nozzle diameter comparison from smallest left to largest right. But you may have wondered about the many nozzle shapes that are available on the market.