Nozzle Definition Welding

Nozzle Definition Welding, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Please anyone clarify whether long pipe has to be consider as a integral part of the vessel long nozzle or after first weld it has to consider as discharge pipe.

Spray nozzle best quality. On one side of this weld joint we find the pressure vessel and on the other side the pipe. Pair with acculock s contact tips d ma250 diffuser acculock mdx liners power pin caps. Acculock s large thread on nozzle 58 orifice 14 tip recess copper miller blister pack 1 per pkg for use with mdx 250 mig guns and bernard btb mig guns.

Nozzles that feature a fiberglass insulator and brass. It is put over and insulator to keep the nozzle from being electrically charged which would short out on the parent metal and shock the heck out of someone not using a glove and seals at the top giving the shielding. I did a project to remove the flange from discharge nozzle underneath the lpg horizontal vessel discharge was welded directly.

The major function of the welding needle or nozzle is to manage and direct the flow of the welding gases. Nozzle a brass attachment that is about three inches long and shaped as an open cylinder. Now the first flange is located 6m away from the vessel.

The best welding nozzle choice will depend largely on your welding application joint access and process. Others offer better access. The nozzle shape and bore size are important in relation to both the size of the welding joint and the current.

Having the right nozzle for the job can help reduce weld defects rework and associated downtime while also extending consumable life. Welding gun nozzles play a critical role in the welding operation. A welding shroud or welding nozzle keeps the gas at the weld puddle.

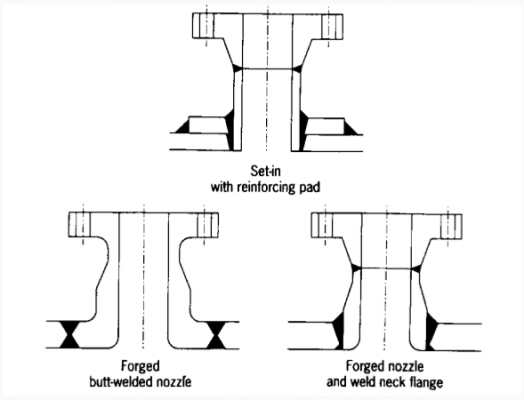

It can be identified by having only one or two pipes running to the nozzle no oxygen blast trigger and two valve knobs at the bottom of the handle letting the operator adjust the oxygen and fuel flow respectively. These bevels are often defined following international codes such as the asme b1625. Both having their own specific design code.

The welding head deriving from previous studies petring et al 2003 integrated hybrid welding nozzle. The main function of your welding nozzle is to direct the shielding gas into the weld puddle in the most effective manner possible. A bevel is commonly machined in both sides of the weld nozzle and pipe following a very specific geometry.

The head contained a single water cooled nozzle for laser and arc and a system for a stable guiding of the wire electrode. A welding torch head is used to weld metals. All of these factors impact the bottom line.

Some welding nozzle designs offer better gas coverage.