Nozzle Design Asme

Nozzle Design Asme, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Design and registration services at pveng.

Nozzle check yellow. Guidebook for the design of asme section viii pressure vessels third edition section viii. As per asme section viii the nozzle and pipe diameter cannot be smaller than the inlet connection of the required psv capacity. A variety of head types are allowed including spherical elliptical asme dished cylindrical and conical.

Criteria and commentary on select aspects of the boiler pressure vessel and piping codes. Run area replacement calculations on asme viii 1 nozzles without repads. Ptc 6 asme flow nozzle this flow nozzle provides high accuracy and precision required by asme ptc 6 in steam turbine testing applications.

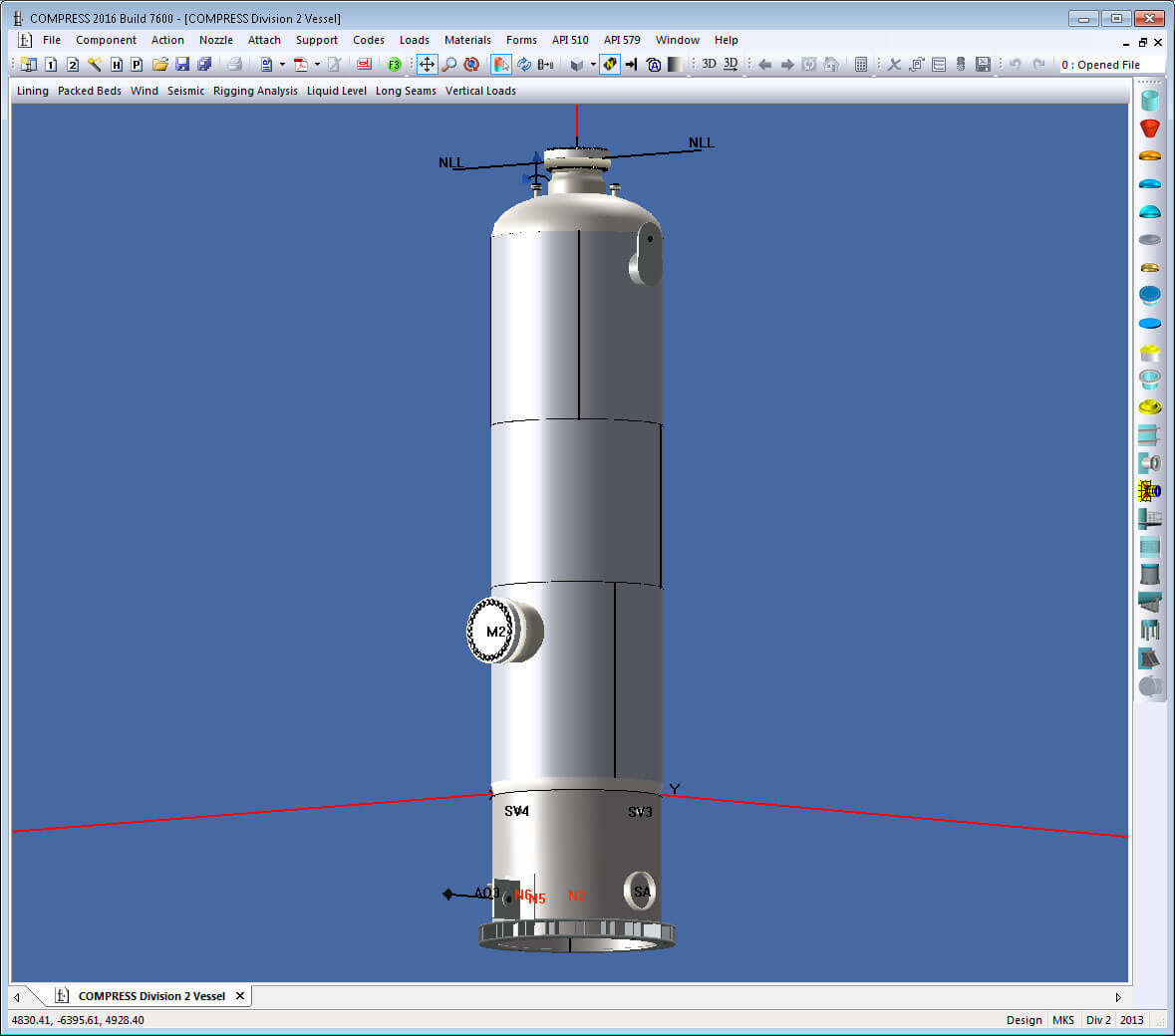

Tower with wind seismic and vacuum loads this tower is designed for a combination of seismic wind and external pressure vacuum loads. The asme flow nozzle is a high performance reliable measurement devicethat can be installed in various design and material configurations with conformance to asme mfc 3m asme ptc 6 and asme ptc 195 codes. Also the psv nozzle connection must be sized to relieve the flow of fluids if the operating pressure reaches a level higher than the maximum allowable working pressure mawp that the vessel was designed for.

A minimum number of values must be input to generate the model. Compress pv elite designcalcs and our own in house software. This atomizer design aims to contact the liquid metal stream with the gas is at or close to the gas jet exit plane where the highest jet velocities exist.

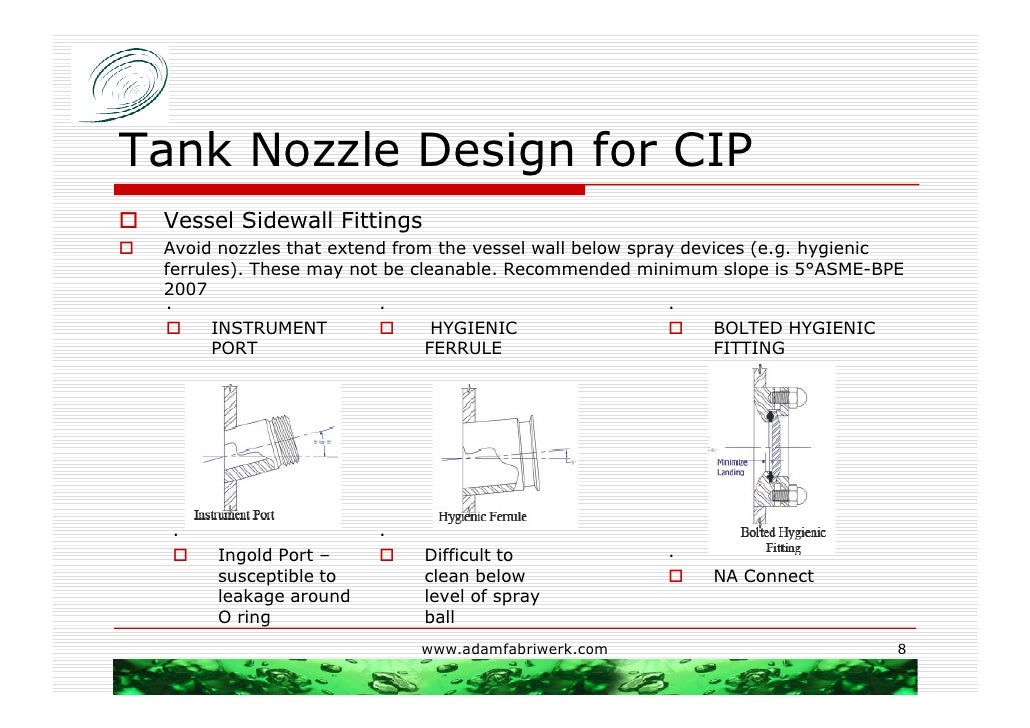

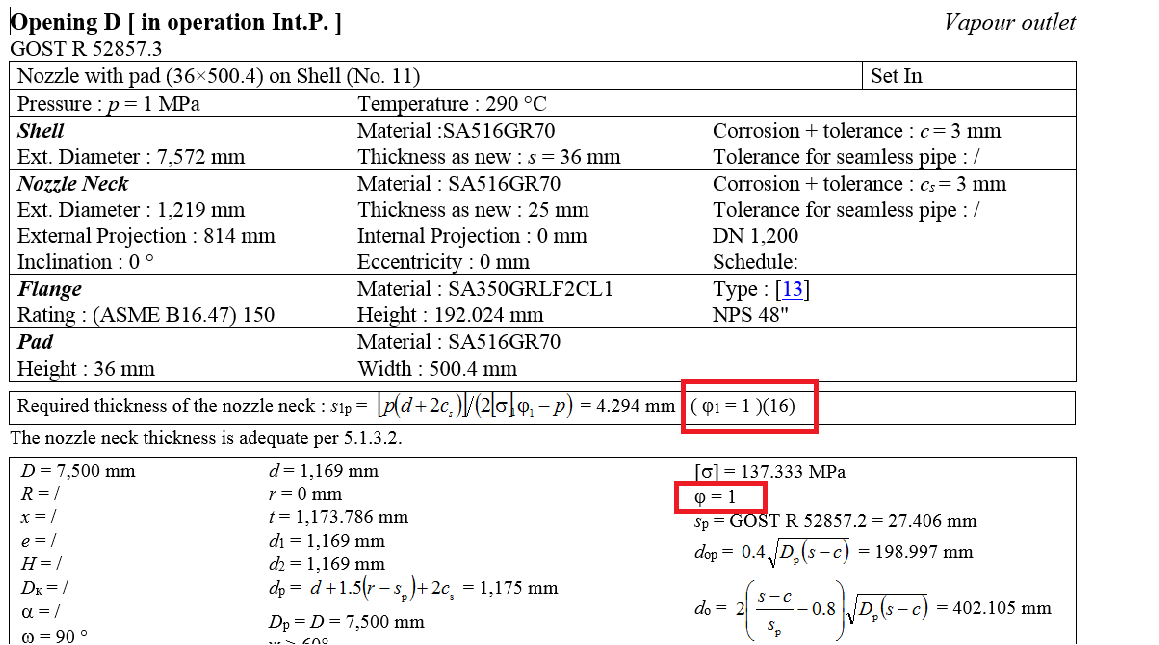

Asme ug 37 nozzles d 1066 hole diameter t 25 actual shell thickness corroded tr 7117 required shell thickness from calculations tn 25 nozzle wall thickness corroded trn 4477 required nozzle thickness from calculations fr1 1 snsv for set in nozzle only maximum 1 note design stress notation sv vessel shell sn nozzle design stress sp pad design stress. Nozzlepro is designed to quickly and easily evaluate nozzles saddles pipe shoes and clips according asme viii division 2. The typical nozzle configuration is with reinforcing plate or reinforcing pad.

In some applications special lethal cyclic high pressure high temperature or high thermal gradients services is recommended to avoid non integral nozzles configuration as per asme code nomenclature. Asme code design we work to many asme standards to design and validate pressure vessels boiler fittings and piping systems.