Nozzle Extrusion Pressure

Nozzle Extrusion Pressure, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

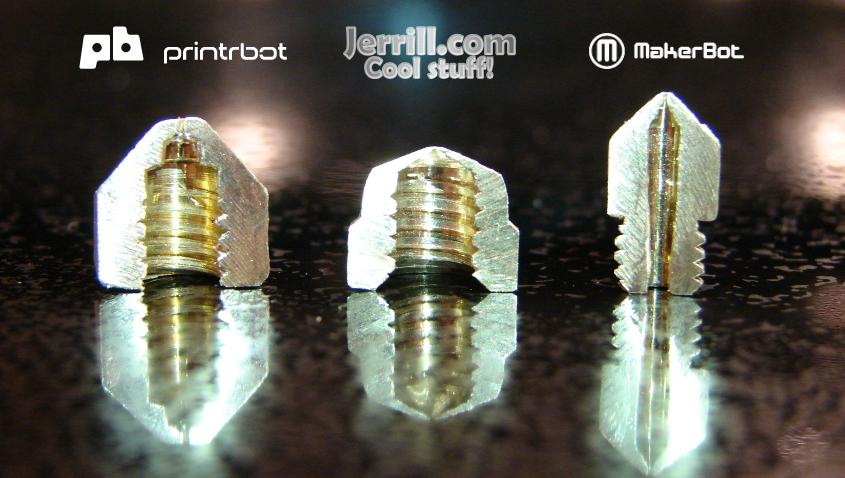

3d Printer Improvements 3d Printing Nozzle Characteristics Silvan Nozzle Kit To Suit All Prograde Sprayers

Investigation Of The Effect Of Nozzle Design On Rheological Bioprinting Properties Using Computational Fluid Dynamics Silvan Nozzle Kit To Suit All Prograde Sprayers

Changing the amount of applied pressure changes the bioinks flow rate which can drastically change the resulting bioprinted construct.

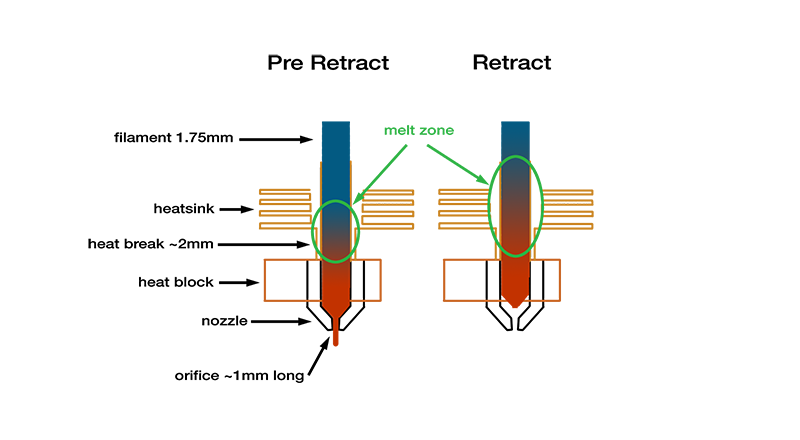

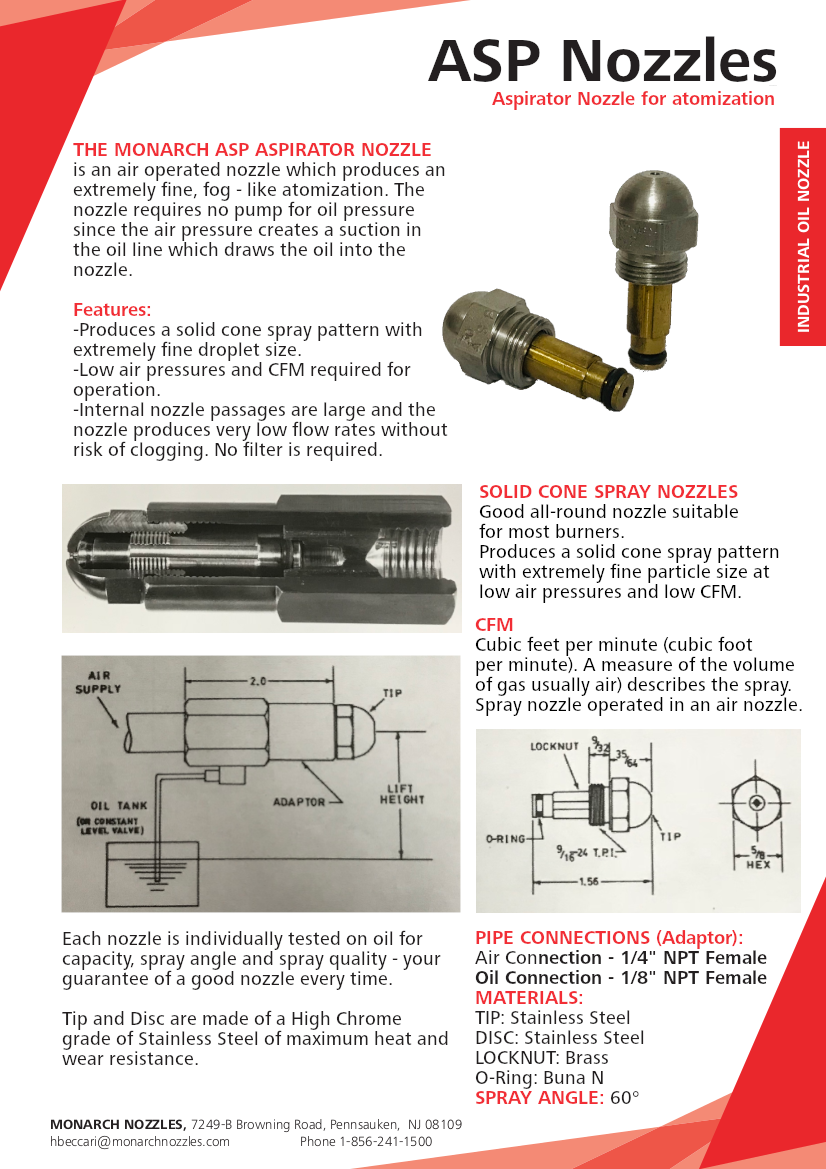

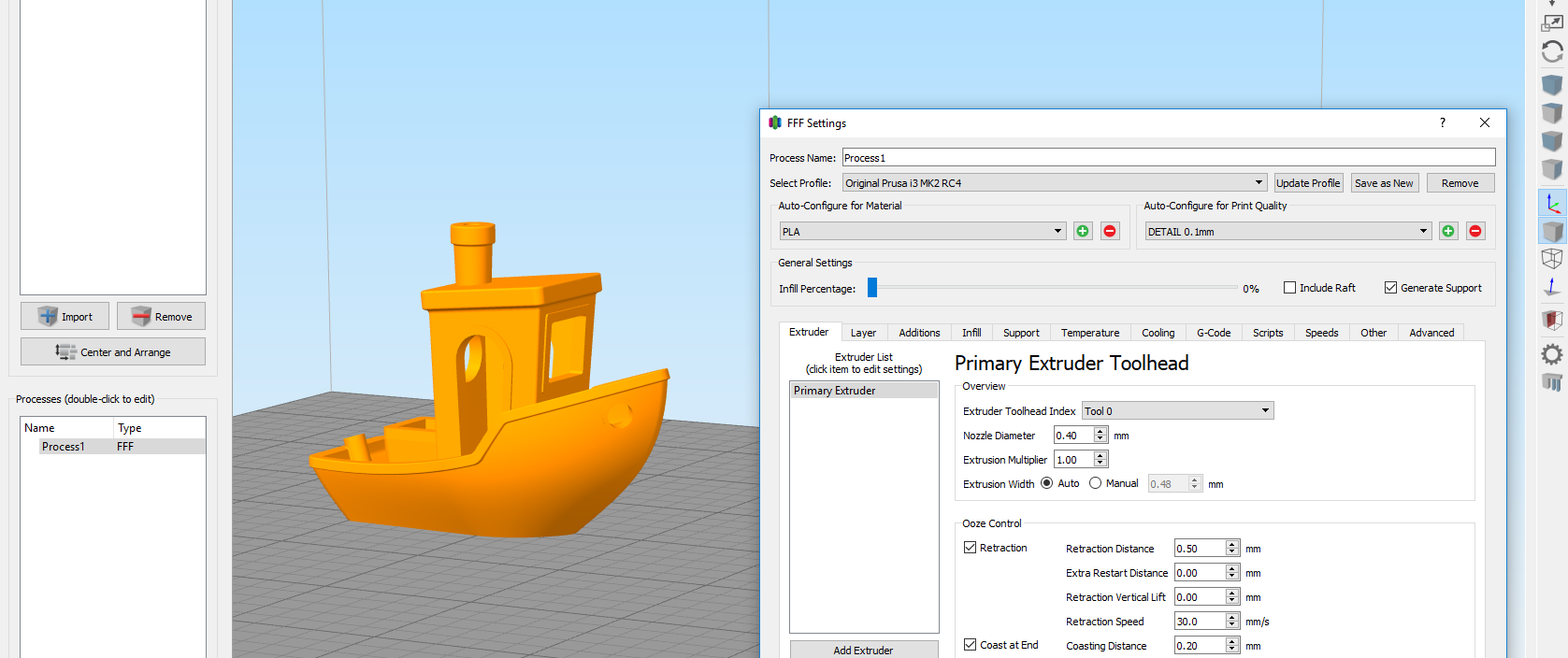

Silvan nozzle kit to suit all prograde sprayers. Nozzles and orifices are often used to deliberately reduce pressure restrict flow or to measure flow rate. On this page well do a deep dive into the effects of pressure on a bioprinted construct. If you extrusion width is significantly smaller than your nozzle diameter this may cause extrusion issues.

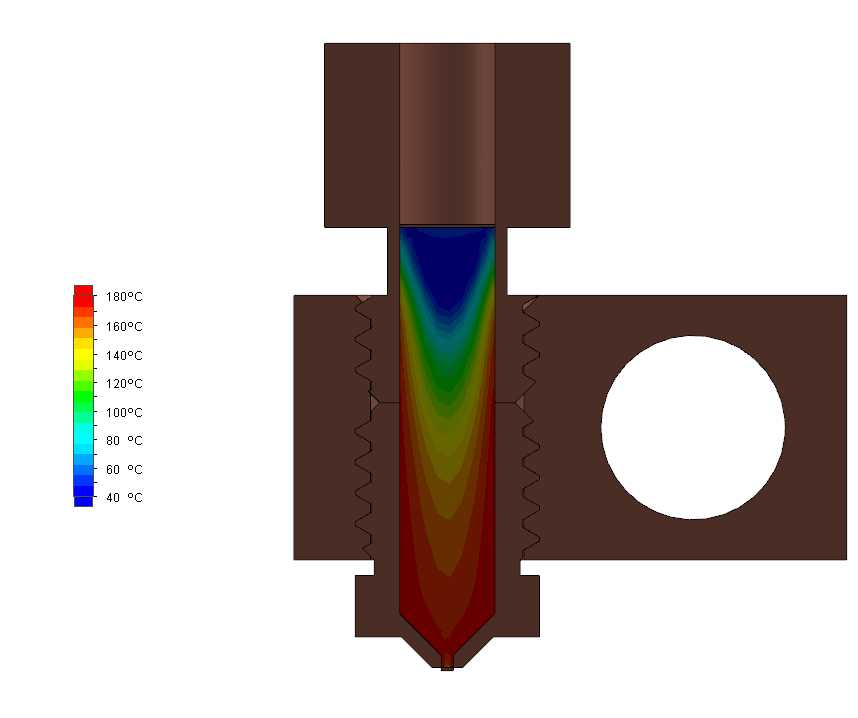

Generally high pressure is caused by narrow nozzle diameters longer throats sharp changes in angle prior to the throat and poor surface finish. Extrusion based bioprinting generates pressure in a cartridge to force a bioink to flow through a nozzle. This helps maintain a steady pressure in the extruder assembly so that the molten filament oozes out of the nozzle at a consistent rate.

This article provides calculation methods for correlating design flow rate and pressure loss as a fluid passes through a nozzle or orifice. Pressure is just one parameter out of many to consider when bioprinting including print speed temperature nozzle size and more. The opening of the nozzle is much smaller than the diameter of the filament.

Another issue thats related is the thermal break between the heater block and the heat sink where heat works its way up to the heat sink and if not fully functional can cause plastic to deform slightly. With the pressure created by the continuous rotation of the extruder gears the molten filament is forced through the nozzle. For a given nozzle geometry and extrusion rate.

Pressure Advance Input From Instrument Measurement Duet3d Silvan Nozzle Kit To Suit All Prograde Sprayers