Nozzle Flow Behaviour

Nozzle Flow Behaviour, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

These include the flow through a jet engine through the nozzle of a rocket from a broken gas line and past the blades of a turbine.

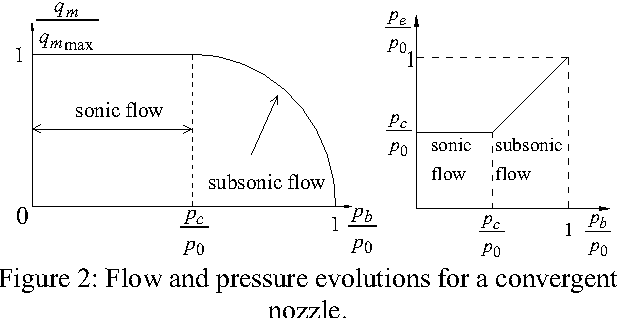

Nozzle spray pump. The mach number reaches the peak value at the nozzle exit plane. In a steady internal flow like a nozzle the mach number can only reach 1 at a minimum in the cross sectional area. The gas flow behavior is compressible.

This nozzle contains an adjustable ring that allows the nozzle firefighter to adjust the flow rate by. When the flow speed reaches the speed of sound. The fluid does not contract any further as it leaves the nozzle and the pressure loss created is considerably less than that occurring with orifice plates.

The analysis of gas flow through de laval nozzles involves a number of concepts and assumptions. Some applications of a nozzle. So when a fluid flows through a nozzle its velocity increases continuously and pressure decreases continuously.

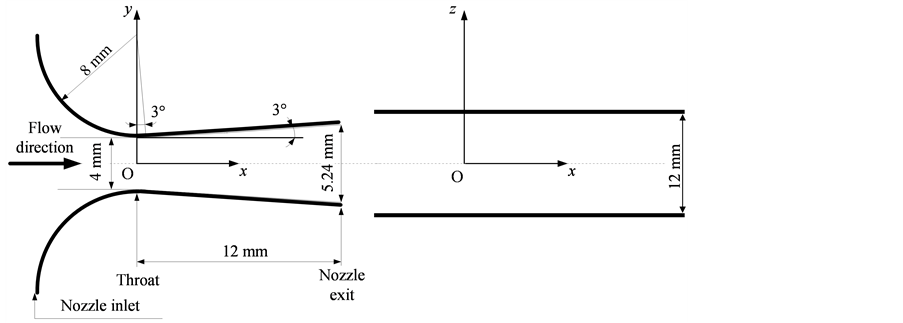

The two models predict almost the same flow behaviour upstream the nozzle throat where water vapour is accelerated with the increase of the mach number. The gas flow is isentropic ie at constant entropy. The choked flow is obtained at the nozzle throat and then the supersonic flow is achieved in the nozzle diverging part.

The gas flow is constant ie steady during the period of the propellant burn. A nozzle is a device a duct of varying cross section area in which a steadily flowing fluid can be made to accelerate by a pressure drop along the duct. At points a and b.

Analysis of gas flow in de laval nozzles. For simplicity the gas is assumed to be an ideal gas. The flow nozzle lies between the orifice plate and the venturimeter both in performance and cost.

The classical quasi one dimensional laval nozzle which has a slender geometry with a rapidly. Several nozzle geometries have been used in propulsion systems. A typical section through a flow nozzle is shown in figure 494 where pressure tappings are located immediately adjacent to the upstream and downstream faces of the nozzle ie.

Nozzles and orifices are often used to deliberately reduce pressure restrict flow or to measure flow rate. Since the gas coming from the exit nozzle is at a higher pressure than the surrounding gas the gas coming from the nozzle will expand outward as soon as it leaves the nozzle. Nozzle is that while the nozzle will provide a known flow rate the flow rate is adjustable.

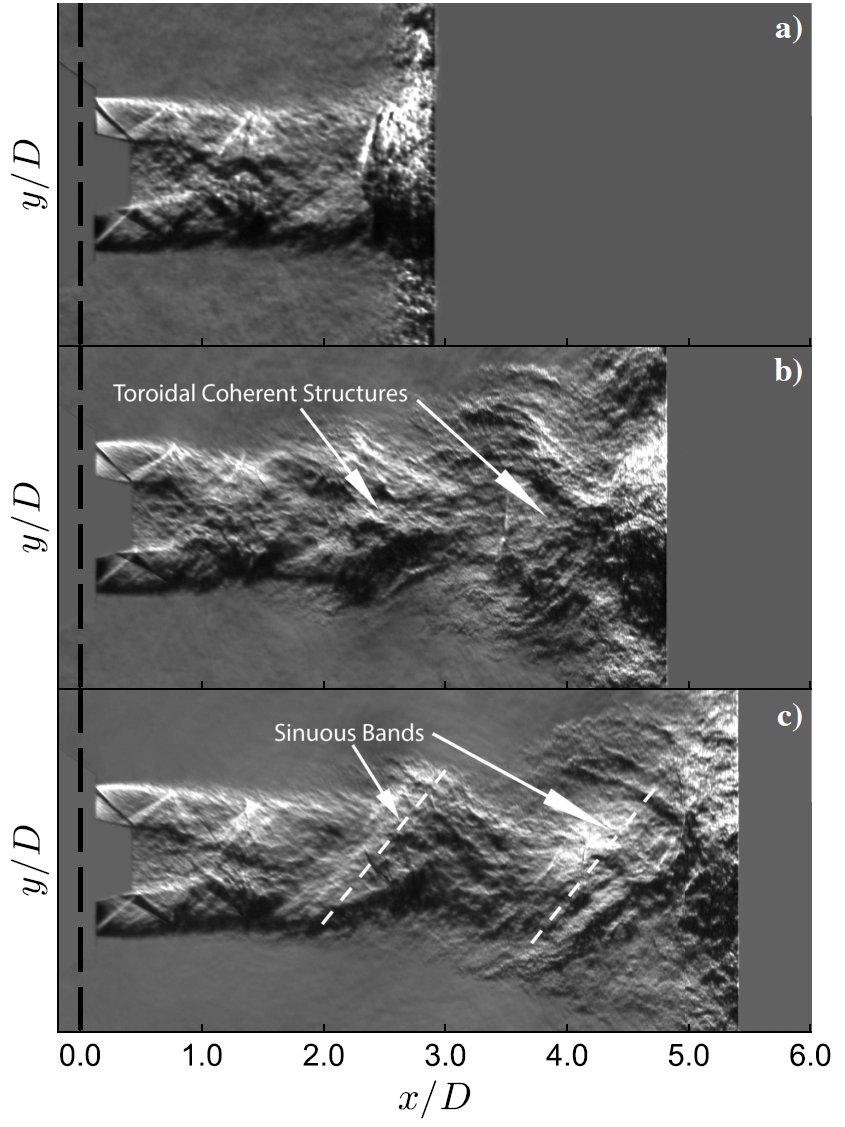

The reason for this behavior has to do with the way the flows behave at mach 1 ie. There are numerous applications where a steady uniform isentropic flow is a good approximation to the flow in conduits. Supersonic flow in cd nozzles presents a rich behaviour with shock waves and expansion waves usually taking place inside andor outside.