Nozzle Flow Fields

Nozzle Flow Fields, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

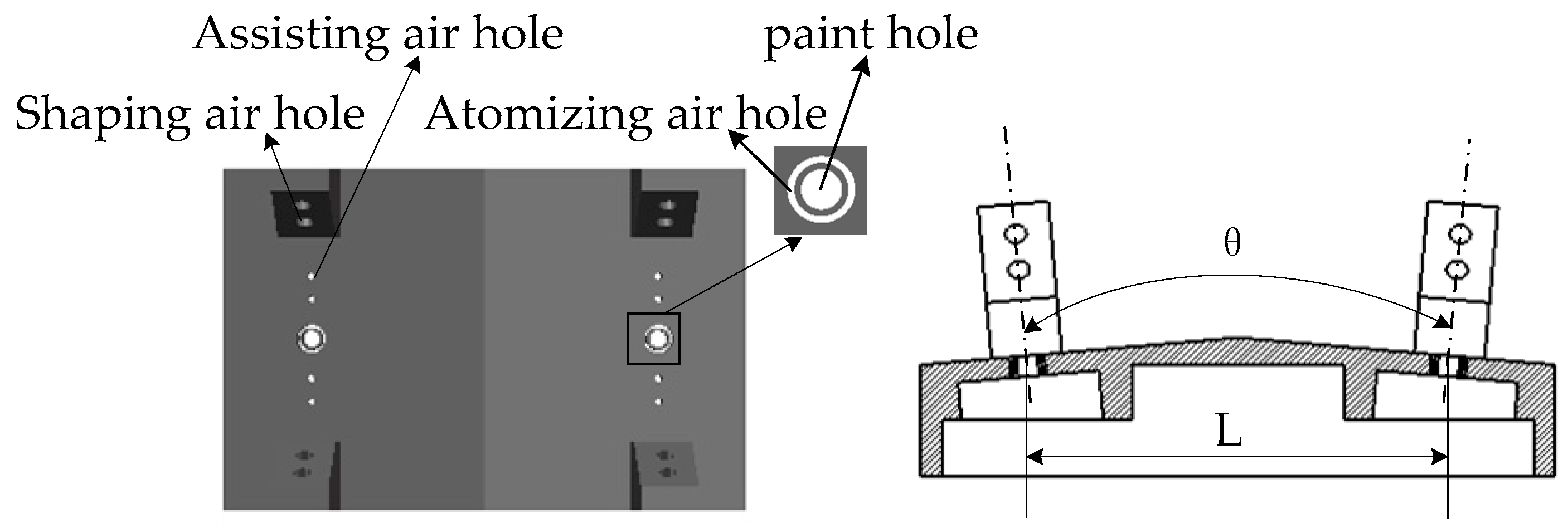

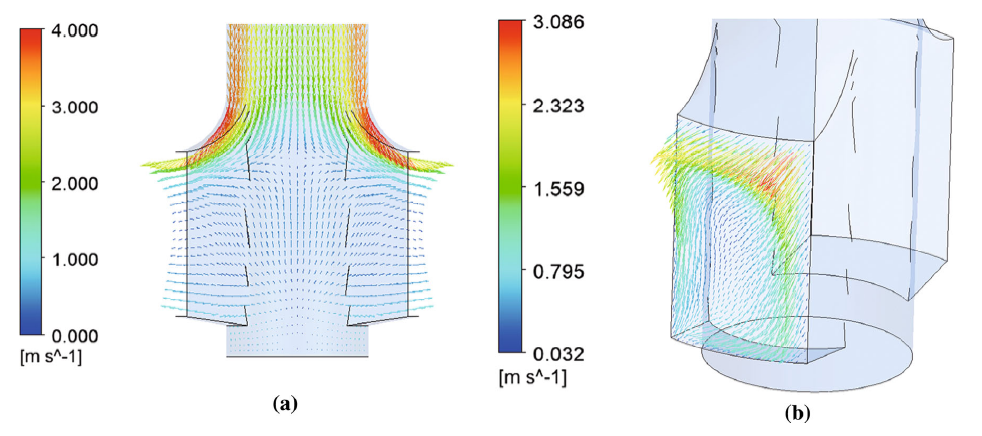

Coatings Free Full Text Design Of A Double Nozzle Air Spray Gun And Numerical Research In The Interference Spray Flow Field Water Jet Hose Nozzle

Structural Optimization Of Electromagnetic Swirling Flow In Nozzle Of Slab Continuous Casting Water Jet Hose Nozzle

Some applications of a nozzle.

Water jet hose nozzle. In reality however nozzle flow fields are at least two dimensional 2 d in nature. A nozzle for a supersonic flow must increase in area in the flow direction and a diffuser must decrease in area opposite to a nozzle and diffuser for a subsonic flow. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure becomes a measure of flow rate.

It can then determinine the interactions between these three flow fields. It uses the classic method of characteristics moc technique to design a jet nozzle and analzye the internal flow field the plume and the external flow near the nozzle exit. A nozzle is a device a duct of varying cross section area in which a steadily flowing fluid can be made to accelerate by a pressure drop along the duct.

The flow coming out of the nozzle is turned in the axial direction and discharged into the atmosphere. The flow passing through the turbine scroll is turned and runs into the nozzle. Several configurations are available the.

That is flow properties vary in both the axial and radial directions. Magnetic field generates lorentz force which brakes the fuel flow in the nozzle generating a converging diverging shape resulting in the velocity increase in the center of the nozzle. The gpm flow rate values given in catalogues or in apps are based on spraying water only.

So when a fluid flows through a nozzle its velocity increases continuously and pressure decreases continuously. We are making it available for beta testing among the nozzle team members. When a flow nozzle is placed in a pipe carrying whose rate of flow is to be measured the flow nozzle causes a pressure drop which varies with the flow rate.

Another important flow element is the flow nozzle. Spraying solutions with higher densities than water most spray solutions are will affect the flow rates of nozzles at the same spray pressure. It was found that the flame length decreased as the magnetic field increased when magnetic field applied to the tip section of the nozzle there was no change for the mid and initial sections though.

Nozzle orifices wear out with time causing larger flow rates and distorted spray patterns than when they were new. In a conventional bell nozzle the gas flowing from the combustion chamber and through the nozzle throat must be turned away from the nozzle axis in order to accelerate or expand the flow. The flow angle at the scroll outlet was designed at 6750.