Nozzle Flow Formula

Nozzle Flow Formula, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Area in square inch n is nozzle size in number32 inch.

Flow nozzle formula. Equation which says that for a nozzle spraying into a room at a pressure. The relationships for flow rate pressure loss and head loss through orifices and nozzles are presented in the subsequent section. V velocity of flow in pipe.

The formula above can be simplified like this. Three nozzles have a diameter of 1032 inch and other 2 nozzles are 1232 inch diameter. V velocity of flow at outlet of nozzle.

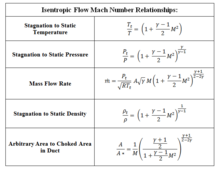

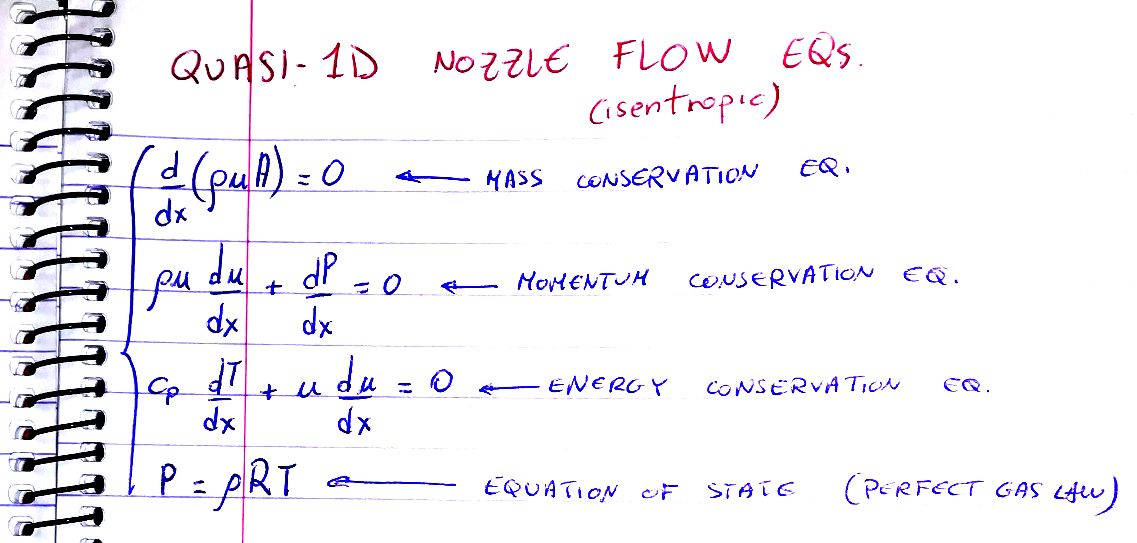

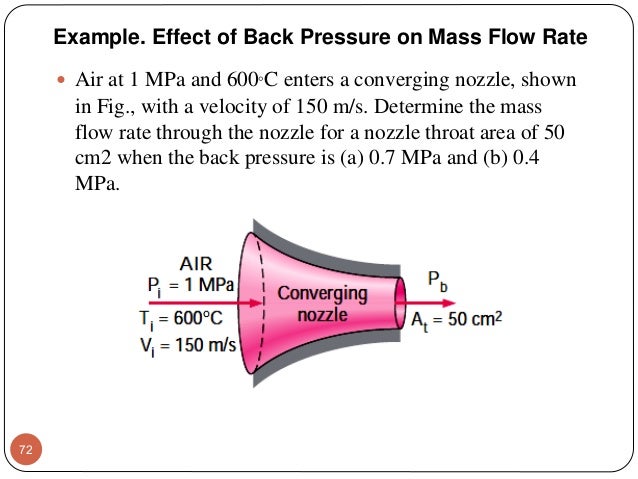

A nozzle for a supersonic flow must increase in area in the flow direction and a diffuser must decrease in area opposite to a nozzle and diffuser for a subsonic flow. B d o d 1. Equation 4 can be modified to mass flow for fluids by simply multiplying with the density.

There is no work done in nozzle therefore w 0. Let us consider the following data from above figure. A area of the pipe.

For unit mass the steady flow equation is q w d h d pe d ke. D diameter of the pipe. Flow area n2 13038 for instant you use a bit that has a total of 5 nozzles.

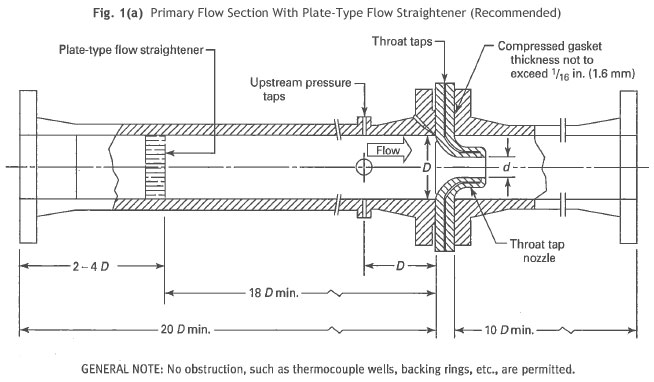

M c d p 4 d 2 2 r 2 p 1 p 2 r 1 d 4 12 5 where. D diameter of nozzle at outlet. Beta b the ratio of orifice to pipe diameter which is defined as.

Qf total test flow rate measured during test in gpm gpm measured from hose monster or pitotless nozzle hr pressure drop from static pressure to desired residual pressure static 20 psi if 20 psi is the desired residual pressure hf actual pressure drop measured during the test static actual residual. For a horizontal nozzle d pe 0. A area of the nozzle at the outlet.

For an air induced nozzle the range is usually from 30 to 90 psi so the middle is 60 to 70 psi. H total head at the inlet of the pipe. D 2 orifice venturi or nozzle inside diameter m in d 1 upstream and downstream pipe diameter m in d d 2 d 1 diameter ratio.

L length of the pipe. These relationships all utilise the parameter. The formula can be rewritten to solve for the unknown nozzle pressure.

Qav considering now two different pressure values for the same no velocity pv2 pgz e on a and section b we can write that the flow energy remains lpvb2 pgzb iately before and immediately after the nozzle outlet orifice len nozzle the a liquid flow. In the nozzle the velocity of the fluid is so high that there is hardly any time available for fluid to exchange heat with the surroundings. Try to operate at a spray pressure thats in the middle of the nozzles operating range.

So for a supersonic flow to develop from a reservoir where the velocity is zero the subsonic flow must first accelerate through a converging area to a throat followed by. Calculating the nozzle reaction for a 125 inch bore diameter nozzle the solid bore discharge formula is gallons per minute gpm 2971 d2 np12.