Nozzle Flow Measurement

Nozzle Flow Measurement, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

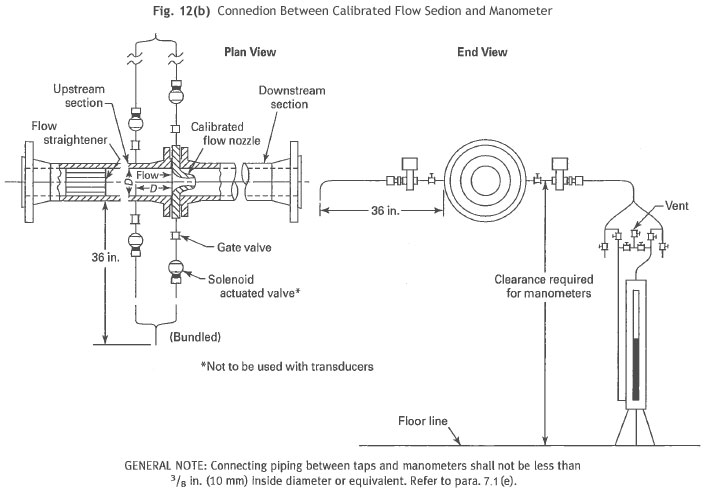

Triad is an industry leader in the design manufacture and testing of ptc 6 flow nozzles for final feed water flow and condensate measurement applications.

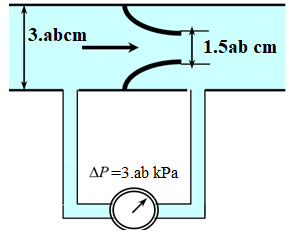

Oil nozzle thread size. When a flow nozzle is placed in a pipe carrying whose rate of flow is to be measured the flow nozzle causes a pressure drop which varies with the flow rate. Here the area of obstruction is constant and the pressure drop changes with flow rate. Basic principle of flow nozzle.

Argon co2 gas flow meter scale tester measure flowmeter for mig tig welder welding 1pk. Differential pressure flow meters. On the other hand rotameter works as a constant pressure drop variable area meter.

Rotameter can be only be used in a vertical pipeline. Nozzles and orifices are often used to deliberately reduce pressure restrict flow or to measure flow rate. The flow nozzle is used for high velocity flow measurement where erosion or cavitation could wear or damage an orifice plate.

As the flow area in a pipe decreases the flow velocity that is accompanied by a decrease in pressure increases in a pipe. Measurement of pipe flow rate can use various flow meters including a differential pressure flowmeter like the orifice meter venturi meter and flow nozzle meter. This article provides calculation methods for correlating design flow rate and pressure loss as a fluid passes through a nozzle or orifice.

Each of these meters operates on the similar principle. Trusted measurement solutions for downstream oil and gas operations. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure becomes a measure of flow rate.

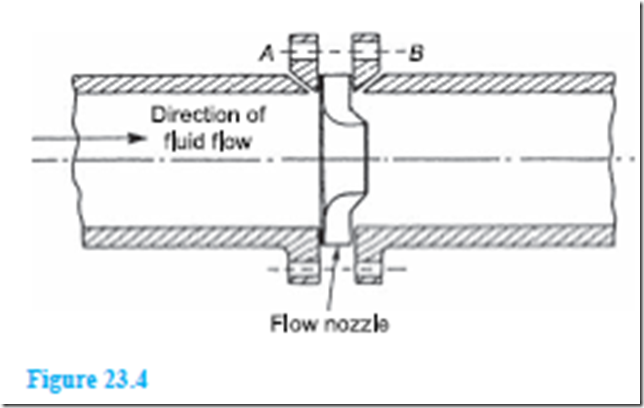

Description of flow nozzle. When a flow nozzle is placed in a pipe carrying whose rate of flow is to be measured the flow nozzle causes a pressure drop which varies with the flow rate. Other types of liquid flow meter are the rotameter magnetic flow meter ultrasonic meter turbine flow meter and coriolis flow meter.

Applying over 100 years of dp flow expertise to industrial processes. Triad manufactures flow nozzles for power generation chemical plants and refineries pipeline and off shore gas processing. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure becomes a measure of flow rate.

These nozzles have a variety of application including feed water steam natural gas etc. The orifice meter the nozzle meter and the venturi meter are the most common devices used to measure the instantaneous flowrate.