Nozzle Flow Work

Nozzle Flow Work, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

The 1 st law of thermodynamics.

Oil nozzle case. This sets the flow being supplied to the proper nozzle pressure and correct velocity for. A nozzle is a device a duct of varying cross section area in which a steadily flowing fluid can be made to accelerate by a pressure drop along the duct. For an air induced nozzle the range is usually from 30 to 90 psi so the middle is 60 to 70 psi.

It is true to say that nozzles do no work in the same way its true normal forces do no work. Due this reduction in cross sectional area the fluid experiences a pressure drop as it exits from the other end of the nozzle but its flow velocity increases consid. Try to operate at a spray pressure thats in the middle of the nozzles operating range.

That means velocity of fluid decreases with increasing pressure. A nozzle is a device designed to control the direction or characteristics of a fluid flow especially to increase velocity as it exits or enters an enclosed chamber or pipe. Their forces are always perpendicular to the direction of motion.

A nozzle is a device used for accelerating the fluid flow at the expense of the fluid pressure. With an automatic nozzle the discharge orifice continually adjusts depending on the flow to the nozzle. No work is involved in nozzles and diffusers.

Summary this article provides calculation methods for correlating design flow rate and pressure loss as a fluid passes through a nozzle or orifice. So when a fluid flows through a nozzle its velocity increases continuously and pressure decreases continuously. Nozzle flow rate chart with volumes at top makes it user friendly.

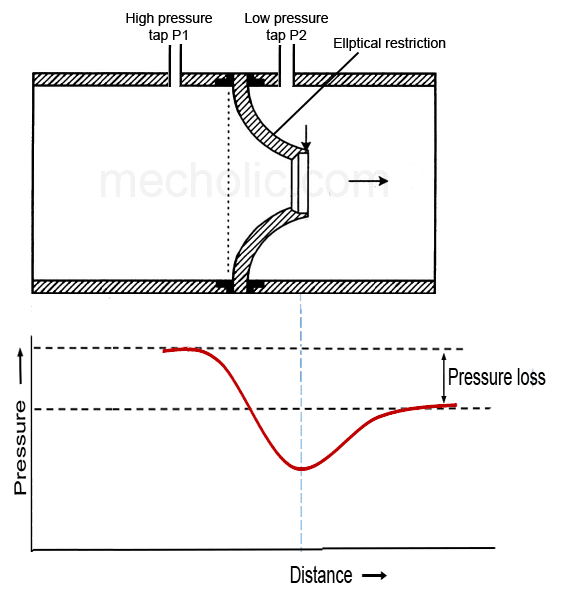

It is true to say that the energy volume doesnt change on a streamline. When a flow nozzle is placed in a pipe carrying whose rate of flow is to be measured the flow nozzle causes a pressure drop which varies with the flow rate. Nozzles are frequently used to control the rate of flow speed direction mass shape andor the pressure of the stream that emerges from them.

Nozzles and orifices are often used to deliberately reduce pressure restrict flow or to measure flow rate. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure becomes a measure of flow rate. During this process velocity of fluid increases with decreasing pressure.

A diffuser is a device which slows down fluid. It is wrong however to conclude that no work is done. A nozzle is often a pipe or tube of varying cross sectional area and it can be used to direct or modify the flow of a fluid liquid or gas.

It is basically a tapering tube with the outlet diameter lesser than the inlet diameter.