Oil Nozzle Patterns

Oil Nozzle Patterns, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Spray Nozzles Spray Nozzle Engineering Information Spray Nozzles Matrimonio Max Pezzali E Debora Pelamatti

Each danfoss nozzle is tested at several different production stages to assure perfect conformity with master nozzles of each series.

Matrimonio max pezzali e debora pelamatti. B solid cone type b nozzles produce a spray that dis tributes droplets fairly uniformly throughout the com plete. Regular inspection and servicing are essential to ensure that it is running reliably and at optimum efficiency. To avoid risks and to perform at its best an oil burner needs the same attention as your car.

Danfoss and hago are world leaders in manufacturing precision spray nozzles to serve a wide variety of applications capacities and spray angles. That is the way the correct nozzle is determined in the laboratory. Beyond this the atomizing patterns are tested visually for regularity and atomizing faults if any.

On 2018 02 26 by mike thanks for the nozzle info. This spray pattern becomes progressively more hollow at high flow rates particularly above 800 gph. Solid cone nozzle type b type b nozzles produce a spray which distributes droplets fairly uniformly throughout the complete pattern.

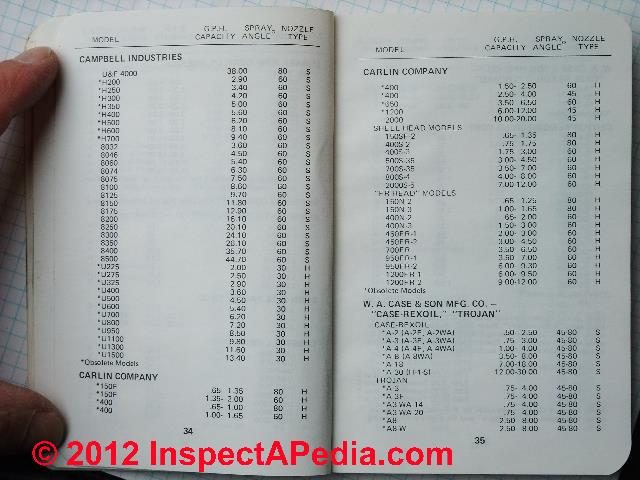

Besides nozzle rate or size in gph and spray angle there are various spray patterns such as solid core hollow core and specialty nozzles like ar anti rumble. Delavan nozzle pattern descriptions black yellow. Del o flotm nozzles are low capacity nozzles designed to minimize the plugging problems associated with.

H hollow and b universal semi solid. Oil nozzle burner. The spray pattern particularly solid vs hollow core is matched to the air flow pattern of the oil burner itself.

The burner combustion system is a factor as is the chamber size and shape. Blue light. Spray patterns of the oil nozzle from left to right.

The sizes of the spray angles are normally 300 450 600 and 800. Danfoss and hago nozzles bringing you performance quality and reliability for over 80 years. We offer both stainless steel and brass varieties and every single one of our nozzles is efficiency tested for performance.

A solid nozzle indicates the vaporized oil is distributed evenly throughout the entire spray pattern. Spray patterns b s and h. Here are some other factors.

Other marks have similar designations. To ensure quality results each nozzle is tested 100 electronically for capacity and spray pattern. A hollow nozzle distributes more of the oil to the outer ring of the pattern and a semi solid is neither.

Over the years correlations have been drawn between burner air patterns and nozzle and chamber configuration and nozzle pattern. The designations of the spray patterns on danfoss oil nozzles are s solid.