Radial Turbine Nozzle Guide Vanes

Radial Turbine Nozzle Guide Vanes, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Simulation Study On The Flow Field Of Guide Vane And Impeller Of Turbo Expander Liu 2019 Energy Science Amp Engineering Wiley Online Library Alemite Grease Gun Nozzle

In this work the influence of thickness and solidity of guide vane on the unsteady flow of a radial inflow turbine with variable nozzle has been numerically studied.

Alemite grease gun nozzle. The velocity triangles are constructed using these various velocity vectors. Radial turbochargers featuring adjustable nozzle vanes ahead of the turbine to vary charge air output are in wide use on automotive diesel engines. Itp aero has two production plants that specialize in precision investment casting with nickel based superalloys.

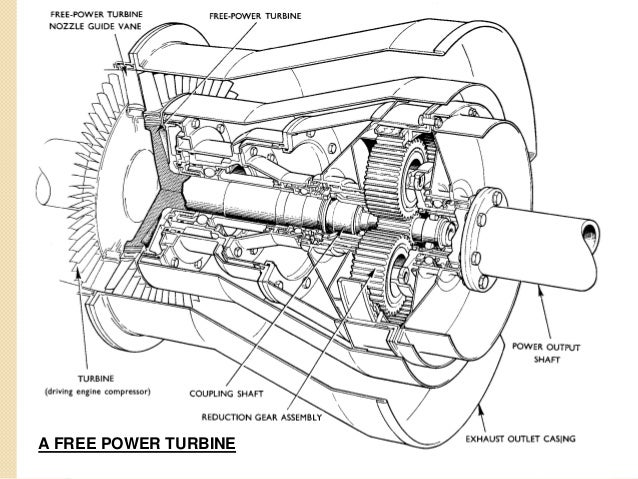

Lower emissions and better fuel economy. Nozzle guide vanes ngvs the stator blades of a turbine. If the turbine is of the radial type the peripheral speed of the turbine should be at or close to the speed of the gas stream entering the turbine.

Gases coming from the combustion chamber pass through the nozzle guide vanes where because of their convergent shape they accelerate. In order to ensure the smooth operation of variable nozzle vanes the actual turbine has clearance gaps for both at the hub and the shroud side. The rotor rotates at velocity u.

They are convex and shaped like airfoils. The number of nozzle vanes and impeller blades are 14 and 9 respectively. End of main content.

The nozzle guide vanes are usually of hollow form and may be cooled by passing compressor delivery air through them to reduce the effects of high thermal stresses and gas loads. Itp aero develops castings for nozzle guide vanes ngvs and radial engine structures. Turbine discs turbine discs are usually manufactured from a machined forging with an integral shaft or with a flange onto which the shaft may be bolted.

Relative to the rotor the velocity of the gas as it impinges on the rotor entrance is v r1. Gas exits the stationary turbine nozzle guide vanes at absolute velocity v a1. The gas is turned by the rotor and exits relative to the rotor at velocity v r2.

They direct the airflow onto the turbine blades while at the same time converting pressure energy into kinetic energy. Man energy solutions has taken up the challenge of transferring this technology to large turbochargers with both axial and radial turbines for installation on large diesel engines burning heavy fuel oil hfo probably the most difficult engine fuel in daily use. Three vanes with the thickness changes from 03 to 01 and the solidity changes from 143 to 286 were chosen for this study.