Rocket Engine Nozzle Exit

Rocket Engine Nozzle Exit, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

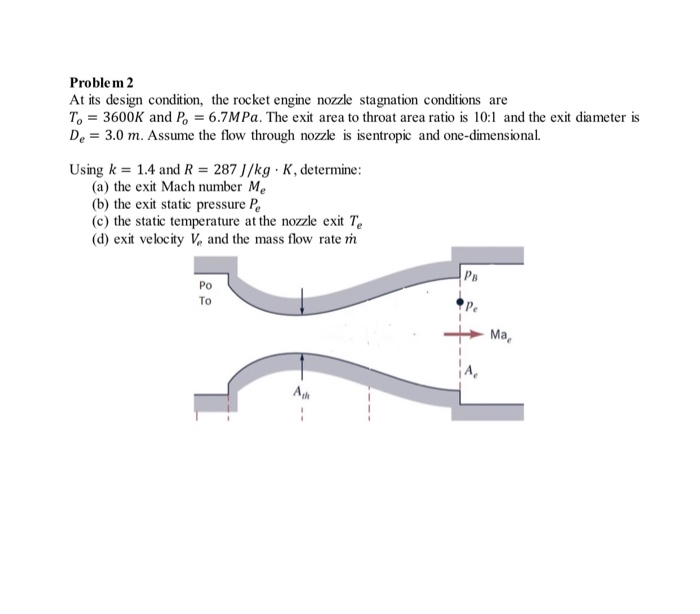

As shown in fig.

Oil burner nozzle near me. This graph shows how a rocket engines thrust depends on the nozzles exit area. Modern versions produce up to 110 kn 24729 lb f of thrust per engine in vacuum. As shown in fig.

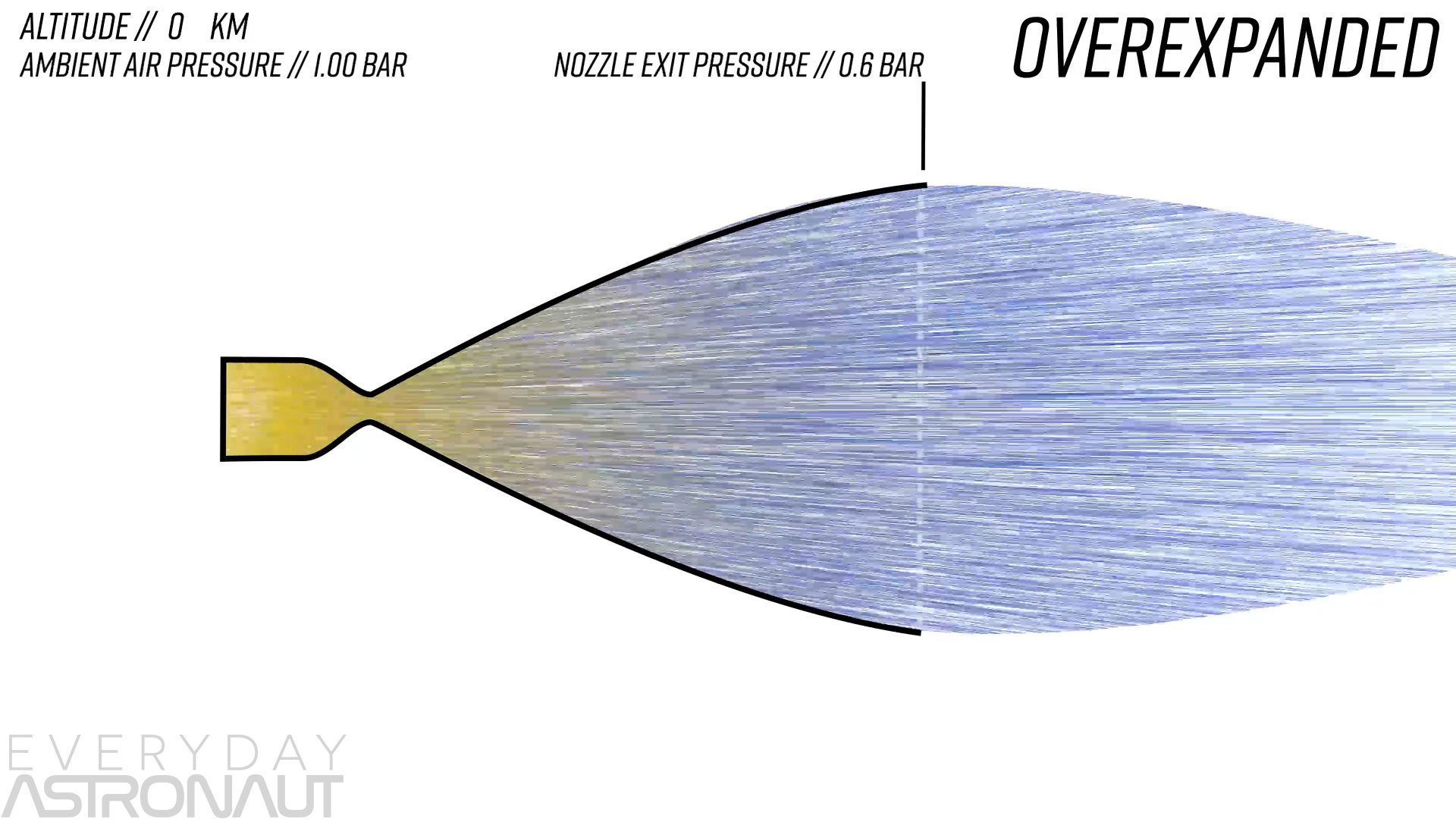

The rocket pumps and a combustion chamber generates high pressure a few hundred atmospheres. A rocket engine nozzle is a propelling nozzle usually of the de laval type used in a rocket engine to expand and accelerate the combustion gases produced by burning propellants so that the exhaust gases exit the nozzle at hypersonic velocities. The value of these three flow variables are all determined by the rocket nozzle design.

The nozzle turns the static high pressure high temperature gas into rapidly moving gas at near ambient pressure. The amount of thrust produced by the engine depends on the mass flow rate through the engine the exit velocity of the flow and the pressure at the exit of the engine. The plenum area ratio aoath and the length of the nozzle are given for pleasing graphics but are not used in the calculation of performance.

1d the laval nozzle has an exit half angle of 30 a nozzle spacing ratio d s d e of 182 and a nozzle expansion ratio d t d e of 017. The ideal rocket engine would make use of a continuously changing rubber or variable geometry nozzle that adjusted contour area ratio and length to match the varying altitude conditions. Rocket engines produce thrust by the expulsion of an exhaust fluid that has been accelerated to high speed through a propelling nozzle.

For nozzle computations the nozzle throat radius rt is used as reference length and the domain size is calculated relative to it. The fluid is usually a gas created by high pressure 150 to 4350 pound per square inch 10 to 300 bar combustion of solid or liquid propellants consisting of fuel and oxidiser components within a combustion chamber. A rocket engine uses a nozzle to accelerate hot exhaust to produce thrust as described by newtons third law of motion.

For example dragging the red line to the right extends the nozzle and increases the exit area. 1 e the structure of the two deflectors is identical except for the shapes of positive impulse area which are the wedge and cone respectively. Three rl10 versions are in production for the centaur upper stage of the atlas v and the dcss of the delta iv.

Typically the outlet is kept at 80 90 rt downstream of the nozzle exit while radially the farfield domain is placed at 70 80 rt from the nozzle central line. If the nozzle exit area could somehow be reduced for launch and then gradually increased during ascent overall mission performance would be improved. The rl10 is a liquid fuel cryogenic rocket engine built in the united states by aerojet rocketdyne that burns cryogenic liquid hydrogen and liquid oxygen propellants.

The hot exhaust is passed through a nozzle which accelerates the flow. Thrust is produced according to newtons third law of motion.