Welding Nozzle Chart

Welding Nozzle Chart, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

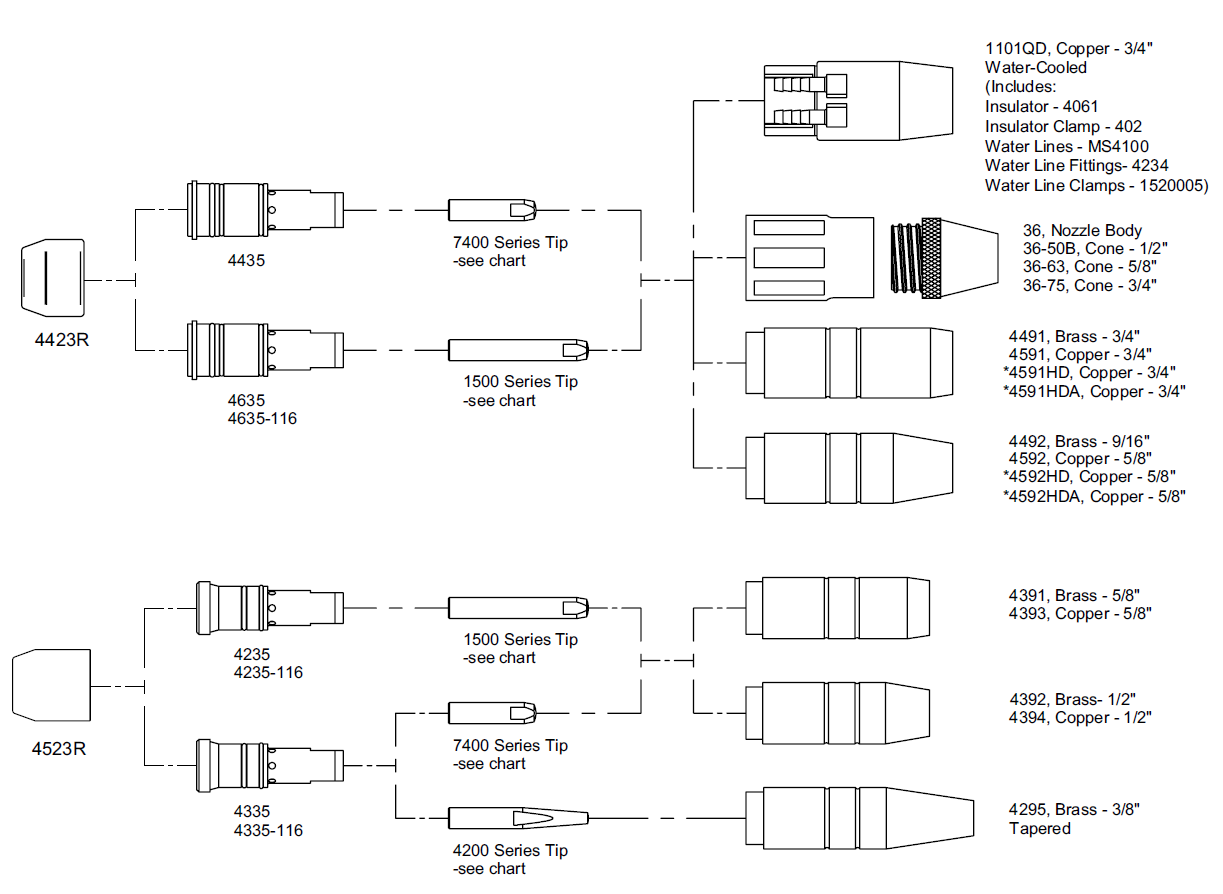

Pair with acculock s contact tips d ma250 diffuser acculock mdx liners power pin caps.

Ender 3 original nozzle. Oxy acetylene welding set up and pressure settings chart. The first we must clean the nozzle because if the head of the nozzle dirty will cause flame bad. For even more protection against high heat the 400 to 600 amps range heavy duty copper nozzles have both thicker walls and thicker insulators.

Mig welding nozzles play an important role in the welding process directing the shielding gas to the weld pool to protect it from contamination and potentially rework. Use mig gun consumables to replace worn parts on your mig guns so you can continue to get your welding jobs done without costly work stoppage. Mig consumables include heavy duty and tapered contact tips self insulated nozzles welding conduit liner and more.

Acculock s large thread on nozzle 58 orifice 14 tip recess copper miller blister pack 1 per pkg for use with mdx 250 mig guns and bernard btb mig guns. The size of the nozzle opening depends on the size of the weld puddle the volume of shielding gas required and the difficulty in reaching the area that needs welding. Welding heating nozzles lightweight swaged copper nozzles for use on orbit torch 14 26 tpi thread.

The reason being is a recessed nozzle allows for the contact tip to sit deeper inside the nozzle and allow for greater gas coverage to the weld. Open regulator oxygen and acetylene set until the pressure matching with what do you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Victor offers a complete range of nozzles tips and elbows with a size for every application including.

Range size quantity 0766232 62401 to 1 mm size 1 1 0766233 62402 1 15 mm size 2 1 0766234 62403 15 2 mm size 3 1 0766235 62405 2 25 mm size 5 1 0766236 62407 25 3 mm size 7 1. Welding brazing heating descaling hard facing flame priming etc. For example when welding deep v groove butt joints a small tapered nozzle may be necessary to get the contact tip close enough to the weld puddle.

Tungsten electrode selector chart tungsten preparation tungsten electrode tip shapes and current ranges tungsten color code and proper torch use color code and alloying elements for tungsten electrode alloys 6correct torch and rod positioning selecting the correct torch nozzle gas lens benefits typical manual gta tig welding parameters. Nozzles designed for optimum performance each complete nozzle has its own built in spiral mixer individually designed for each tip size and flame characteristic.