Allowable Nozzle Loads Table

Allowable Nozzle Loads Table, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Thermal Design Considerations For Centrifugal Compressor Piping Systems Page 2 Of 3 Compressortech Jet Pump Nozzle Design

What are nozzle loads.

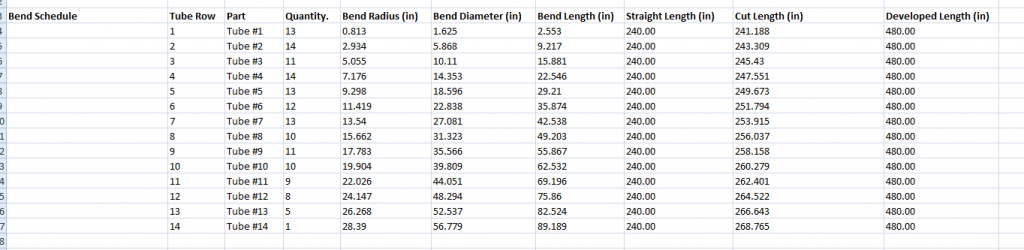

Jet pump nozzle design. The allowable loads and moments listed in table 7 14 do not represent any actual loading or a real maximum allowable load or moment. Every epc company must have project specific pressure vessel nozzle loading tables which are used for comparing allowable nozzle loads for vessels columns or towers heat exchangers drums or any similar type of equipment. This procedure does not take into account any of the vessel parameters such as diameter thickness material temperature allowable.

Rather they are arbitrary maximum allowable nozzle loads. The allowable nozzle loads for brazed aluminium plate fin heatexchanger shall be 3 times the value in alpema standards of thebrazed aluminium plate fin heat exchanger manufacturers association table 5 1. In the event the loads are exceeding the allowable loads values prior approval from the supplier shall be taken.

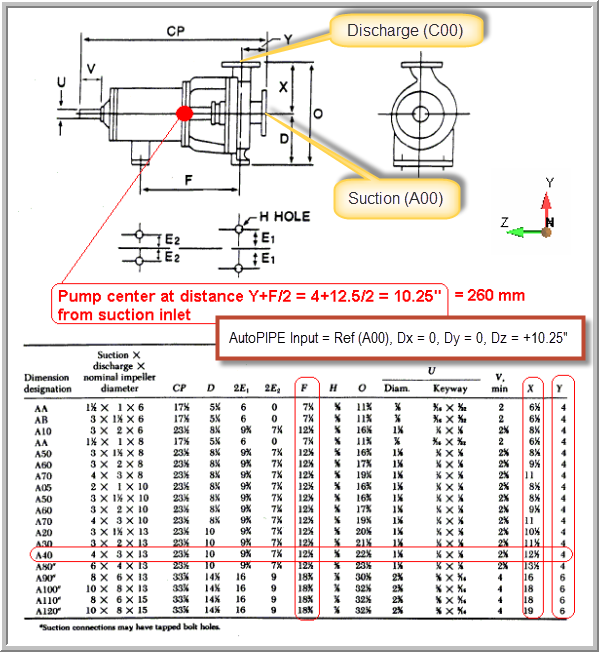

Increased nozzle loads are a cause of misalignment and increased wear and vibration rates in pumps. However it shall be approved and agreed by the vendor. The loads exerted on equipment are directly related to how the equipment and piping are supported.

The wall thickness of pipe is nearly always selected based on the thickness required for. C k f auxiliary value k f 2 1 t w d h 226 t table 4. Nozzle individual flange loads.

The allowable nozzle load table is generated based on the following two parameter. The machinery nozzle loading value that is provided by the manufacturer a code or standard with which the equipment is stated to be compliant or calculated by a method specified by a code or standard. Allowable nozzle load anl.

Normally forces and moments at the nozzle and shell interconnection are provided in a tabular format. For engineers training explains in detail how to design piping systems against primary longitudinal stress sustained longitudinal stress and their limits. Air cooled heat exchangers.

The individual permissible forces and moments which can be applied independently on a nozzle follow from the application of the procedure described above. The nozzle diameter and. All api equipment codes have formulas or tables for allowable nozzle loads.

In some organizations the table value is multiplied with some factors normally 075 while checking nozzle loads for shell and tube heat exchangers. Sustained loads and occasional loads are among the most important concerns as per asme b313 codethus little peng. Nozzle loads are the net forces and moments exerted on equipment nozzles from the weight and thermal expansion of connected piping and equipment.

As a minimum the piping stress engineer shall ensure that the loads on the nozzle of the mechanical equipments are within these values.