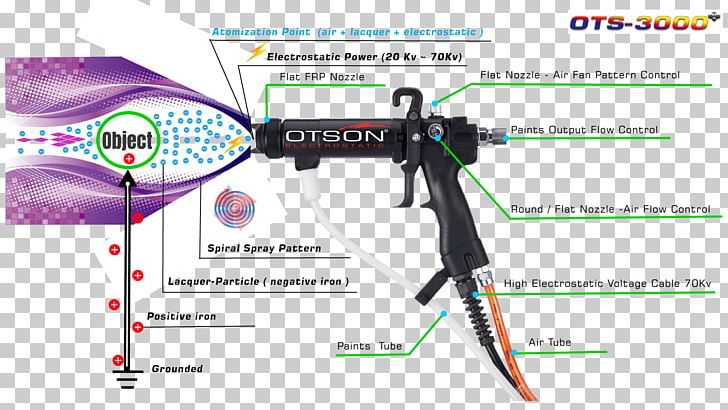

Electrostatic Nozzle Design

Electrostatic Nozzle Design, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

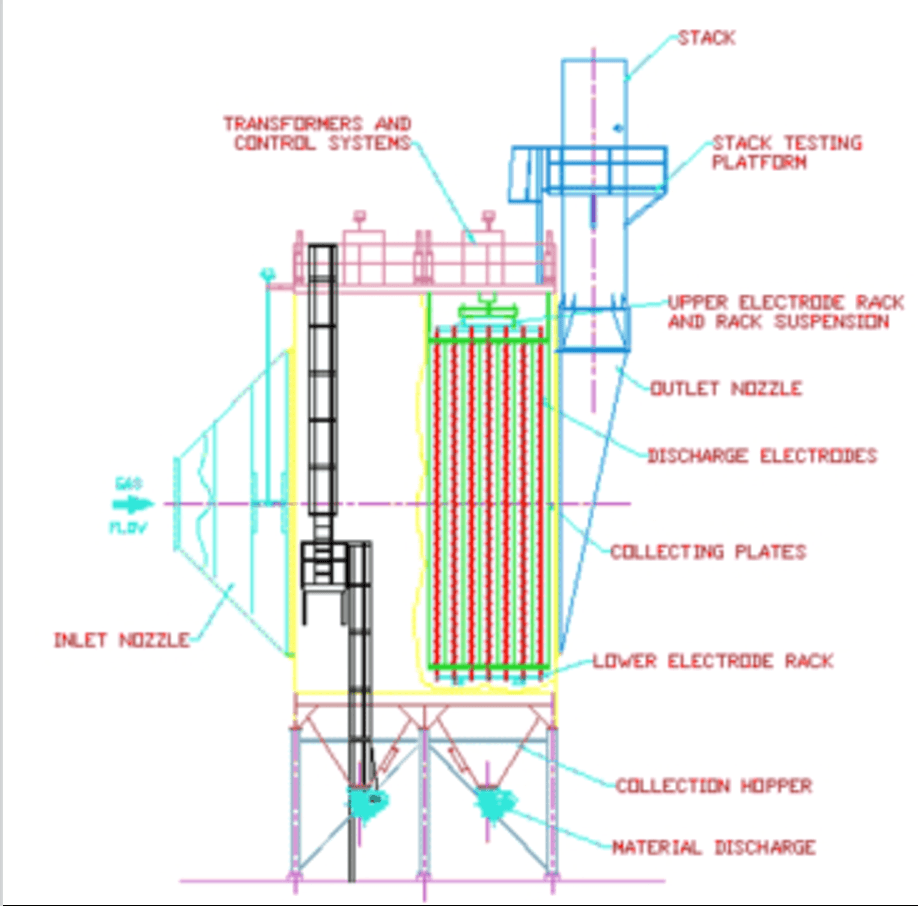

The technology transfer package incl.

Pressure vessel nozzle design calculation excel. The battery can be used at any time to charge and discharge. The electrostatic spray charging nozzle includes a nozzle cap having an. Byoplanet electrostatic spray systems provide greater surface coverage in less time with less solution.

31 ptfe actuator in the current study ptfe was selected as the insulating actuator material representing the most electronegative polymer in the triboelectric series 33. The effect of actuator nozzle designs on pmdi aerosols electrostatic charges and aerosols performance have been investigated and results are discussed below. The diameter of the nozzle is relatively thin and the mist is 4 times thinner than conventional electrostatic sprayers which means it will effectively coat and disinfect surfaces.

The technology is available for manufacturer for adaption. An electrostatic spray charging nozzle designed for optimum charge level over a wide range of liquid and air flow rates. The desired attributes of electrostatic spraying are uniform deposition onto both directly exposed or obscured crop surfaces which minimize the off target losses of active ingredients to soil.

The Effect Of Space Charge On The Performance Of An Electrostatic Induction Charging Spray Nozzle Sciencedirect Pressure Vessel Nozzle Design Calculation Excel