Fuel Nozzle Gas Turbine

Fuel Nozzle Gas Turbine, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Fuel to the primary diffusion fuel nozzles and single tertiary premixing fuel nozzle.

Steam nozzle experiment. As mentioned previously its use requires a flow divider but at the same time it offers a desirable spray pattern for combustion over a wide range of operating pressures. The duplex fuel nozzle is widely used in present day gas turbine engines. Tuesday may 19 2020.

Our advanced engineering expertise combined with leading edge equipment delivers reliable extended life for new or refurbished fuel nozzle products. Gas turbine engine fuel nozzle test procedures arp4865 the intent of this sae aerospace recommended practice arp is to define and recommend to the aerospace industry standardized test procedures for establishing fuel nozzle operating performance including types of tests controlled and measured parameters and test configurations. It is therefore essential to establish a fundamental basis for fuel injection modeling that involves various atomization processes.

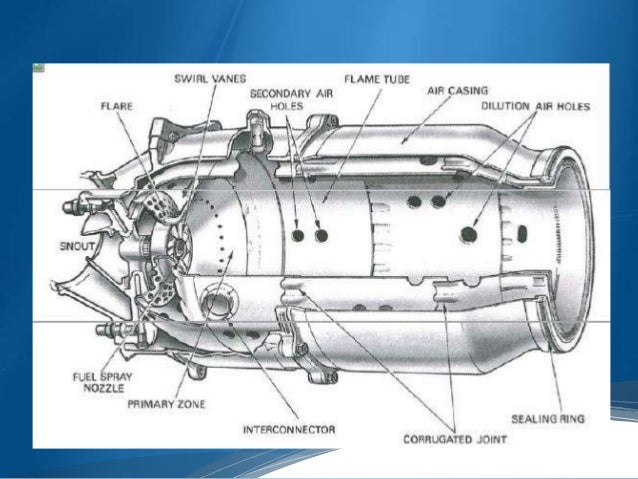

Satisfactory performance of the gas turbine combustor relies on the careful design of various components particularly the fuel injector. Room1142xincheng square no151zidingxiang road. Integrated combustion solutions ics also known as mda fuel nozzle services is a worldwide leader in the repair testing and manufacture of gas turbine fuel nozzles for industrial and power generation customers.

Parker produces fuel nozzles to customers designs for a wide variety of industrial gas turbines utilizing the most advanced manufacturing techniques and equipment. Our diagnostic skills and enhanced reporting add an extra measure of value to the reconditioning of gas turbine fuel nozzles. Figure 6 a nozzle typical of this type is illustrated in figure 7.

The percentage of primary fuel flow is modulated throughout the range of operation as a function of combustion reference temperature. This mode is used from 81 corrected speed to a pre selected combustion reference temperature. Mda is a worldwide leader in the production of gas turbine fuel nozzles through the integration of integrated combustion solutions ics.

Gas turbine fuel nozzle services. Fern engineering has the experience and capabilities to expertly repair heavy frame fuel nozzles.