Nozzle Load Calculation Asme

Nozzle Load Calculation Asme, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

Asme viii 1 viii 2 i iv b311 b313 b315.

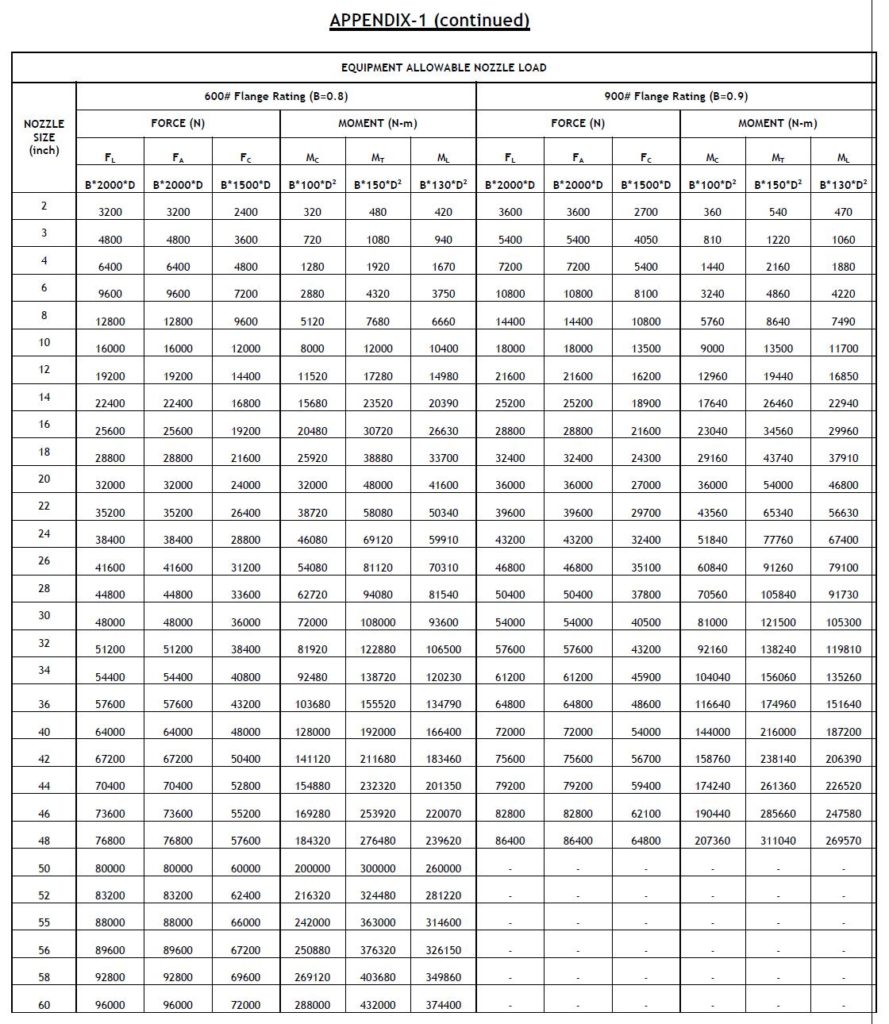

Filter nozzle ksh k1. F sqrt f v 2 f h 2 m sqrt m l 2 m c 2 the loads stated above shall be used as the design basis for nozzles. When loadings in excess of above listed standard allowable nozzle loadings are required the supplier will be informed when the information becomes available. The loads and load combinations must be based on a technically accepted methodology and applicable to all nozzle sizes pressure classes schedules and vessel diameters and thicknesses and reinforcement designs within the scope of the tables.

After determination of the reference loads f and m the following load cases as indicated in table 1 should be considered in the stress analysis of the relevant nozzles. Pressure thermal wind and seismic load analysis. The equations used in b313 are.

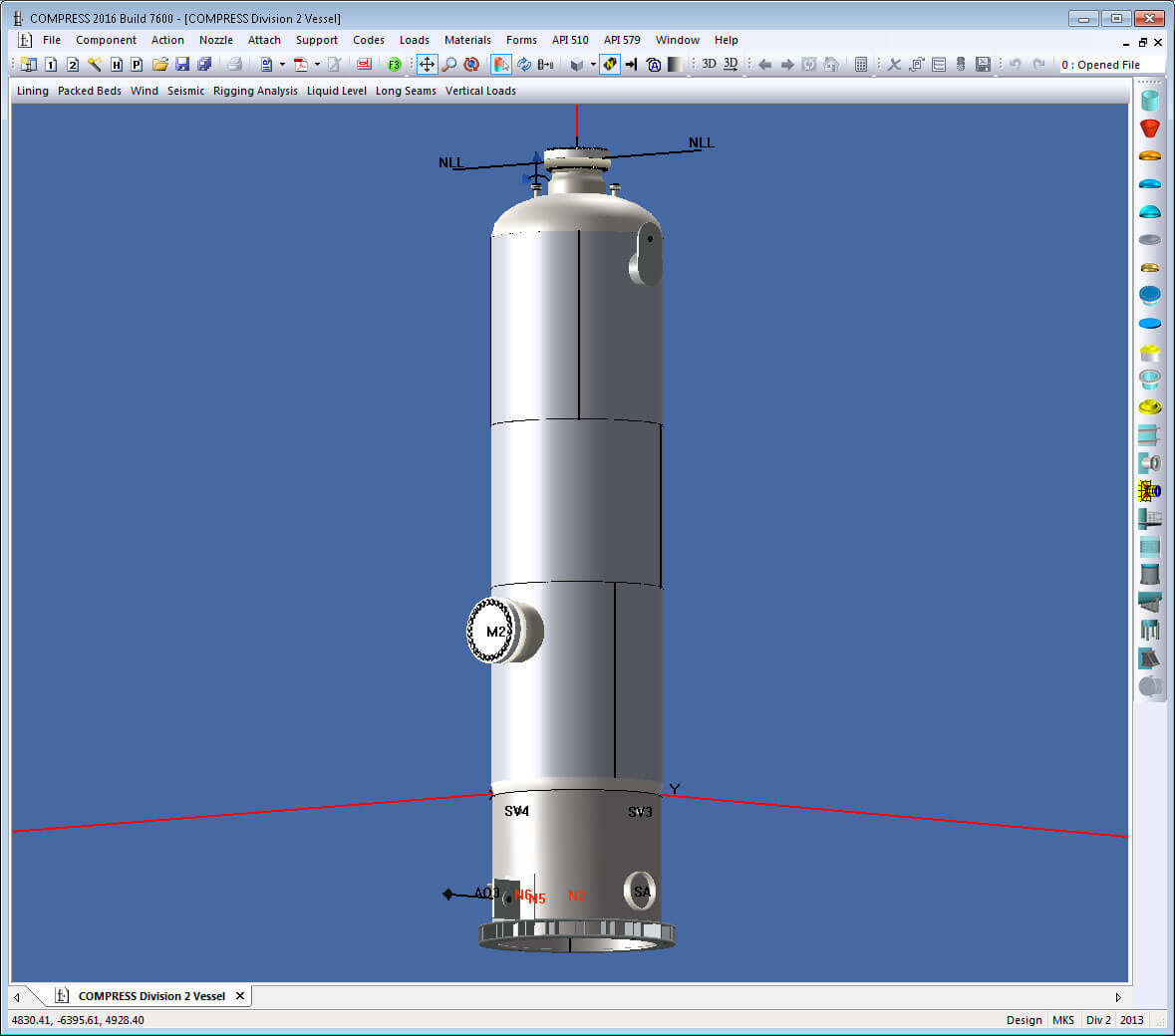

To serve the vessel designer in his effort to calculate the permissible nozzle loads all quantities units and formulas are displayed in the forms shown below tables 1 4. This may be provided by increasing the wall thickness of the shell or nozzle or by adding a reinforcement plate around the opening. The local loads f n and m n.

This has long been a requirement of the ug 22 loadings rules so it is nothing new. The sum of all longitudinal stress including both sustained and occasional loads is limited to 133 times the basic allowable stress. T thickness of pipe in p internal pressure in pipe psi d outside diameter of pipe in s allowable tensile stress psi e quality factor for the piping according asme 313.

In 2017 the asme released code interpretation bpv viii 1 16 85. T p d 2 s e p y 1 where. At some openings there may be a nozzle to which is attached external piping generating external forces and moments from dead loads or thermal expansion.

Maximum allowable individual loads nozzle on cylinder wo reinforcing pad. Asme b1647 4085 mpa. P r rated pressure asme b165 or asme b1647 mpa.

This differs from the pressure vessel code which uses a factor of 12. Finite element analysis fea we use fea to design and validate fittings and vessels that cannot be designed by rule based codes like viii 1 or b313. Mm are the local loads to be introduced with directions according to figure 1.

The asme b313 code is consistent with the structural codes in the treatment of occasional loads.