Plasma Cutting Nozzle Size Chart

Plasma Cutting Nozzle Size Chart, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

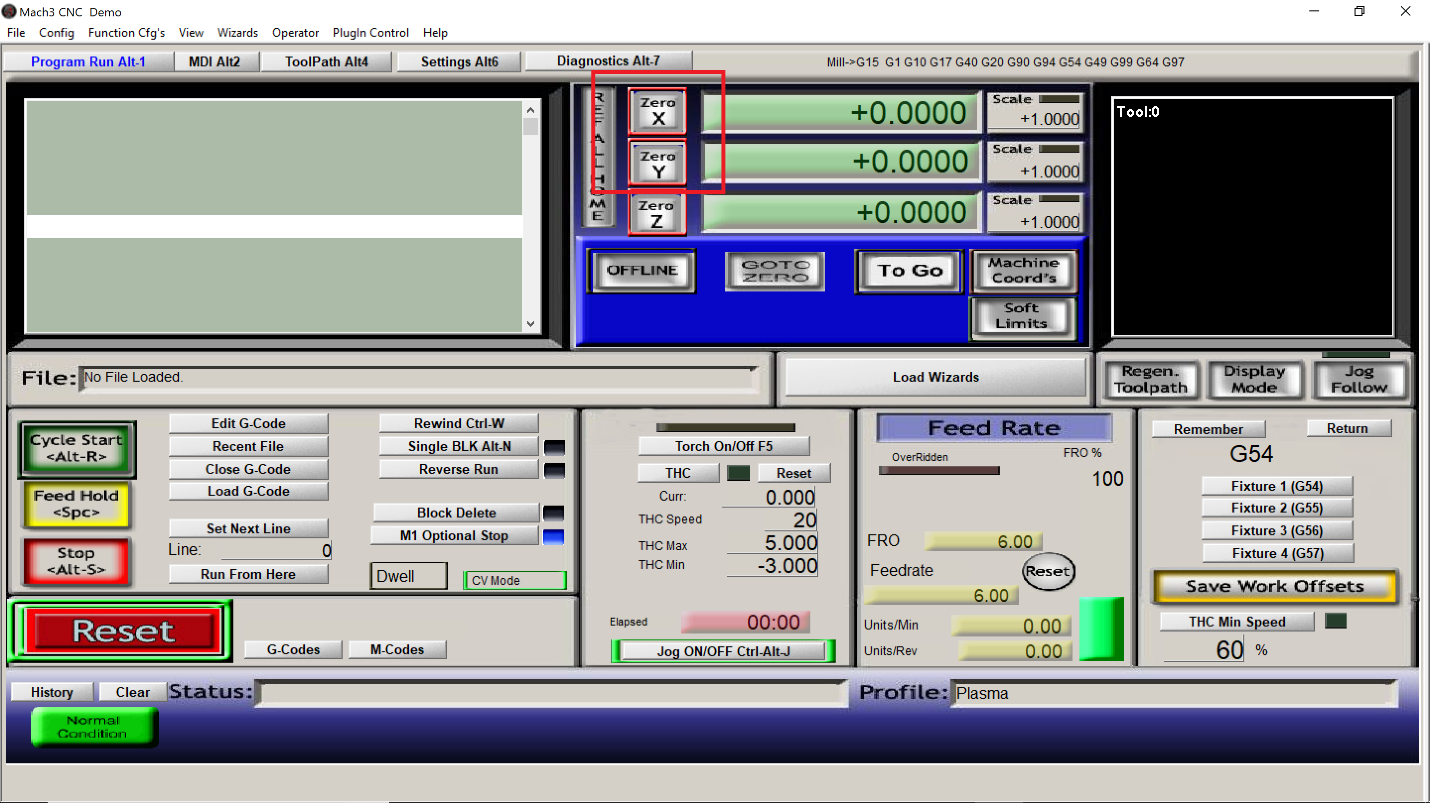

Plasma arc cutting is a process where an open arc can be constricted by passing through a small nozzle or orifice from the electrode to the workpiece.

Airbrush pinch nozzle. 1 above water cutting pages 4 11 through 4 33 and 2 under water cutting where the water table water is 3 above the top. 2 plasma o 2 shield 30 a cutting 220173 220194 220313 220180220193 220192 pierce complete is recommended for these thicknesses note. 220673 shield 220713.

A consumable diagram with part numbers precedes each section. Air must be connected to use this process. Cutting nozzles arcnm rivet nozzle agnm gouging.

Increasing cut speed lowering the torch standoff. Eastwood 40amp versa cut plasma cutter. Cutting nozzles arcnm rivet nozzle agnm gouging.

Recommended cut speeds are a good starting point for finding the best quality cut. Cut charts the following cut charts show the consumable parts cutting speeds and the gas and torch settings required for each process. When cutting thin metal 3 mm10 ga or thinner you may achieve a higher cut quality by using the t30v powermax30 30 a consumables and cut charts.

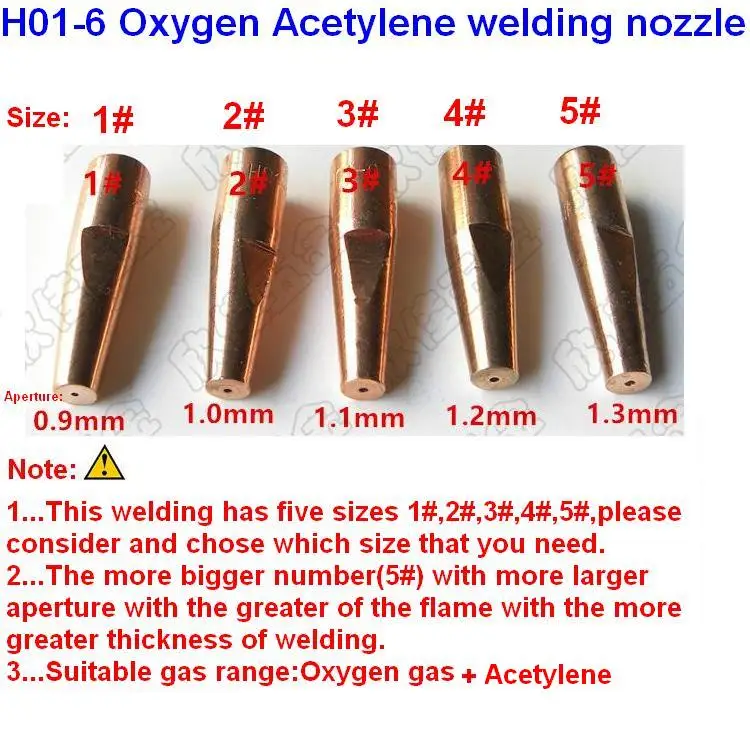

Although the technology behind the plasma arc may seem complicated the process itself is very easy to learn and perform. The cut charts are divided into two areas. Welding tip chart ing thread size chart printable how a plasma cutter works cruizar gas cutting nozzle 1 16.

Prices for automated air plasma cutting systems range between 3500 40 amp and 10000 125 amp. Whether you are cutting thin sheet metal on your project vehicle or heavier metal up to 78 eastwoods versa cut plasma cutters. Using the cut charts the following sections provide cut charts for each set of mechanized consumables.

Cutting nozzle size chart. By eva july 25 2020. Maximum cut speeds are the fastest speeds possible to cut material without regard to cut quality.

T45m shielded consumables the cut charts for these consumables are shown on the following pages. Cut charts the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Eastwoods versa cut plasma cutters are the professionals and diys choice in plasma cutters.

Speeds for your application and your table to obtain the desired cut quality. Keep in mind that these charts provide a good starting point and that optimum cutting must be tuned to the application and materials on site.