Rocket Engine Nozzle Cooling

Rocket Engine Nozzle Cooling, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

A Rr Nozzle Model With Cooling Channels B Computational Grid Download Scientific Diagram Nozze Mistiche Di Santa Caterina Da Siena

The regenerative cooling system which flows cold liquid hydrogen through tubes surrounding the nozzle is an essential element of the design.

Nozze mistiche di santa caterina da siena. The design incorporates a greatly simplified combustion chamber a reduced number of engine parts and the removal of the f 1 exhaust recycling system including the turbine exhaust mid nozzle and the curtain cooling manifold with the turbine exhaust having a separate outlet passage beside the shortened main nozzle on the f 1b. The subjects discussed are 1 regenerative cooling 2 transpiration cooling 3 film cooling 4 structural analysis 5 chamber reinforcement and 6 operational problems. However heat is transferred to the thrust chamber walls in quantities sufficient to require attention.

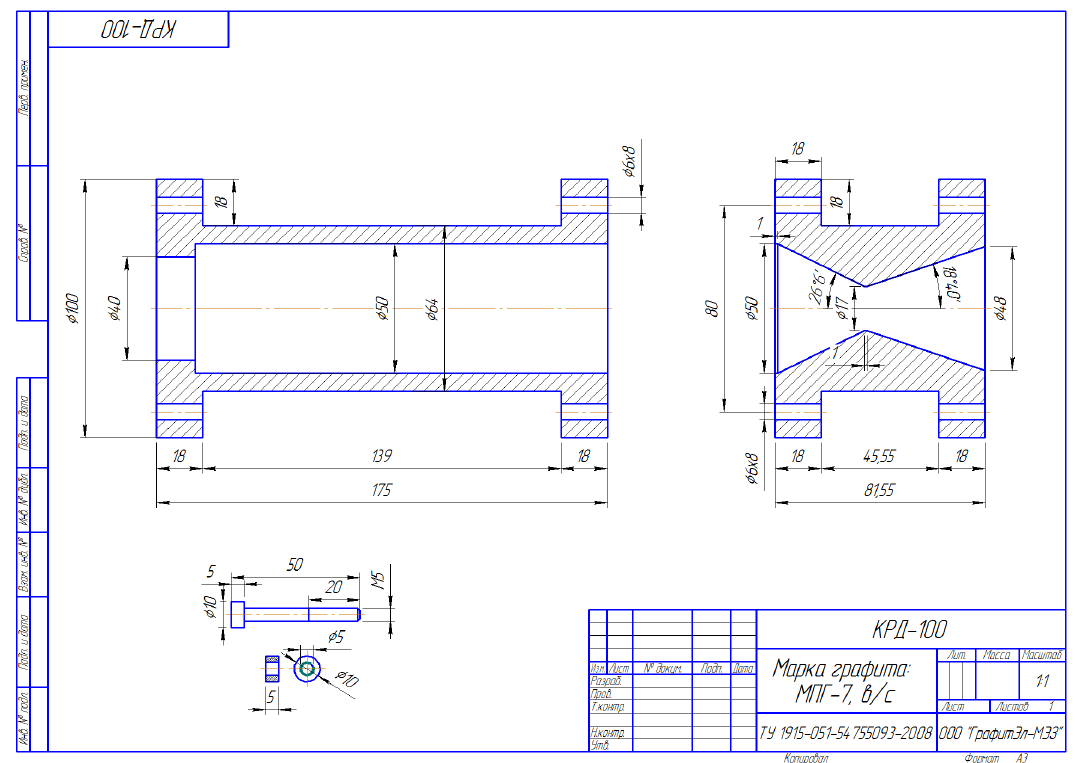

Nozzle cooling nuclear rocket engines ae designed to operate at extremely hot temperatures to maximize efficiency. Cooling in liquid rocket. Summary of the invention the present invention is directed to the formation of cooling channels over the variable diameter length of a rocket engine combustion chamber having a convergent divergent.

Regenerative cooling in the context of rocket engine design is a configuration in which some or all of the propellant is passed through tubes channels or in a jacket around the combustion chamber or nozzle to cool the engine. Most gas generator engines use the fuel for nozzle cooling. Modern actively cooled engine nozzles may be constructed using channel wall technology pioneered in russia.

This is effective because the fuel and sometimes the oxidizer are good coolants. Some of the propellant is burned in a gas generator and the resulting hot gas is used to power the engines pumps. The gas is then exhausted.

Most of this heat is expelled along with the gas that contains it. This complex regenerative cooling system with labyrinthine internal ducts cannot be milled or cast in conventional ways says riede. They may be welded or spinformed.

Liquid systems enable higher specific impulse than solids and hybrid rocket motors and can provide very high tankage efficiency. All liquid rocket engines have tankage and pipes to store and transfer propellant an injector system a combustion chamber which is very typically cylindrical and one sometimes two or more rocket nozzles. The gas generator cycle is a power cycle of a bipropellant rocket engine.

Liquid rocket engine fluid cooled combustion chambers a monograph on the design and development of fluid cooled combustion chambers for liquid propellant rocket engines is presented.