Rocket Nozzle Wall

Rocket Nozzle Wall, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

It employs a fast expansion radial flow section in the initial divergent region which leads to a uniform axially directed flow at the nozzle exit.

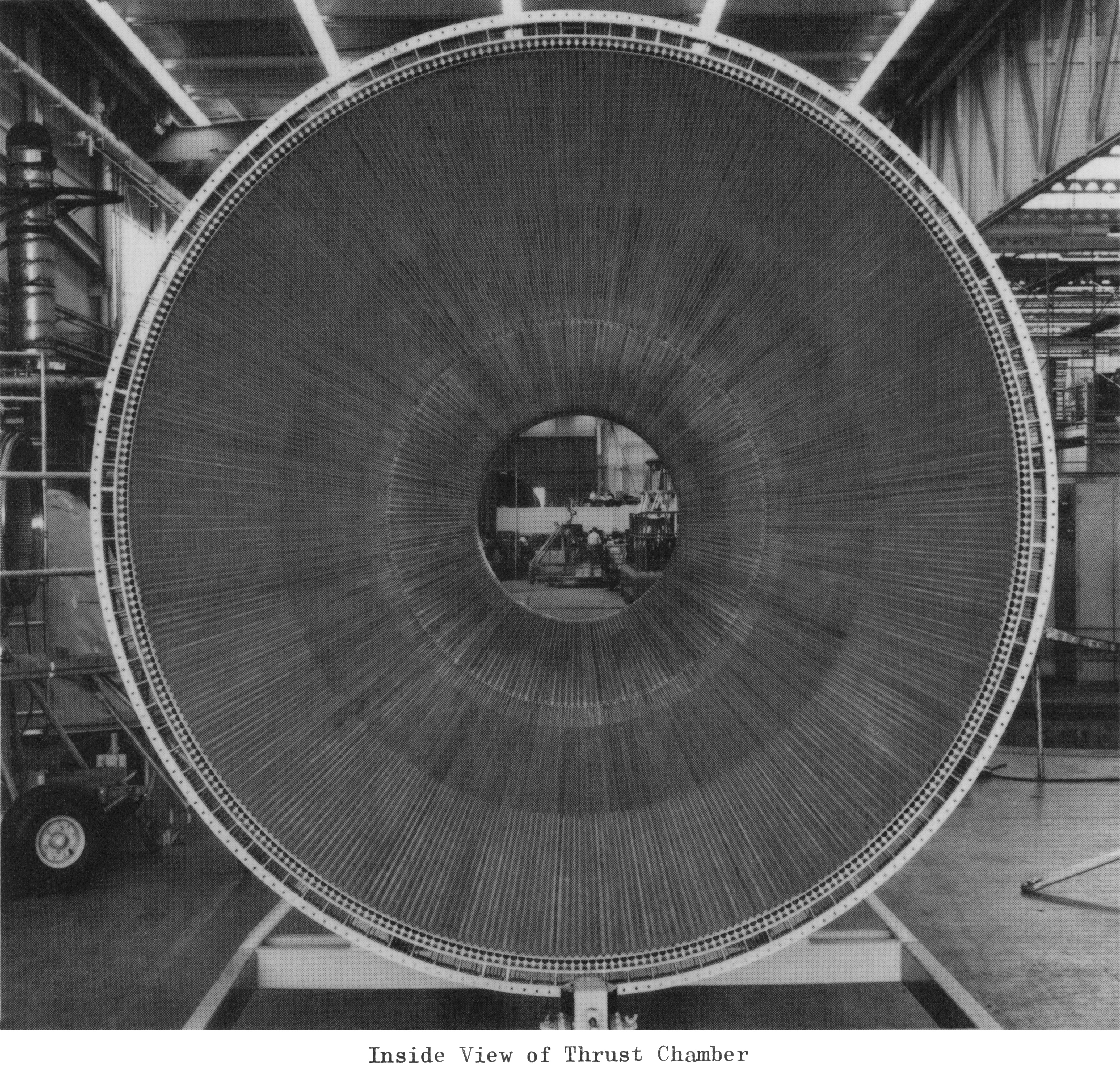

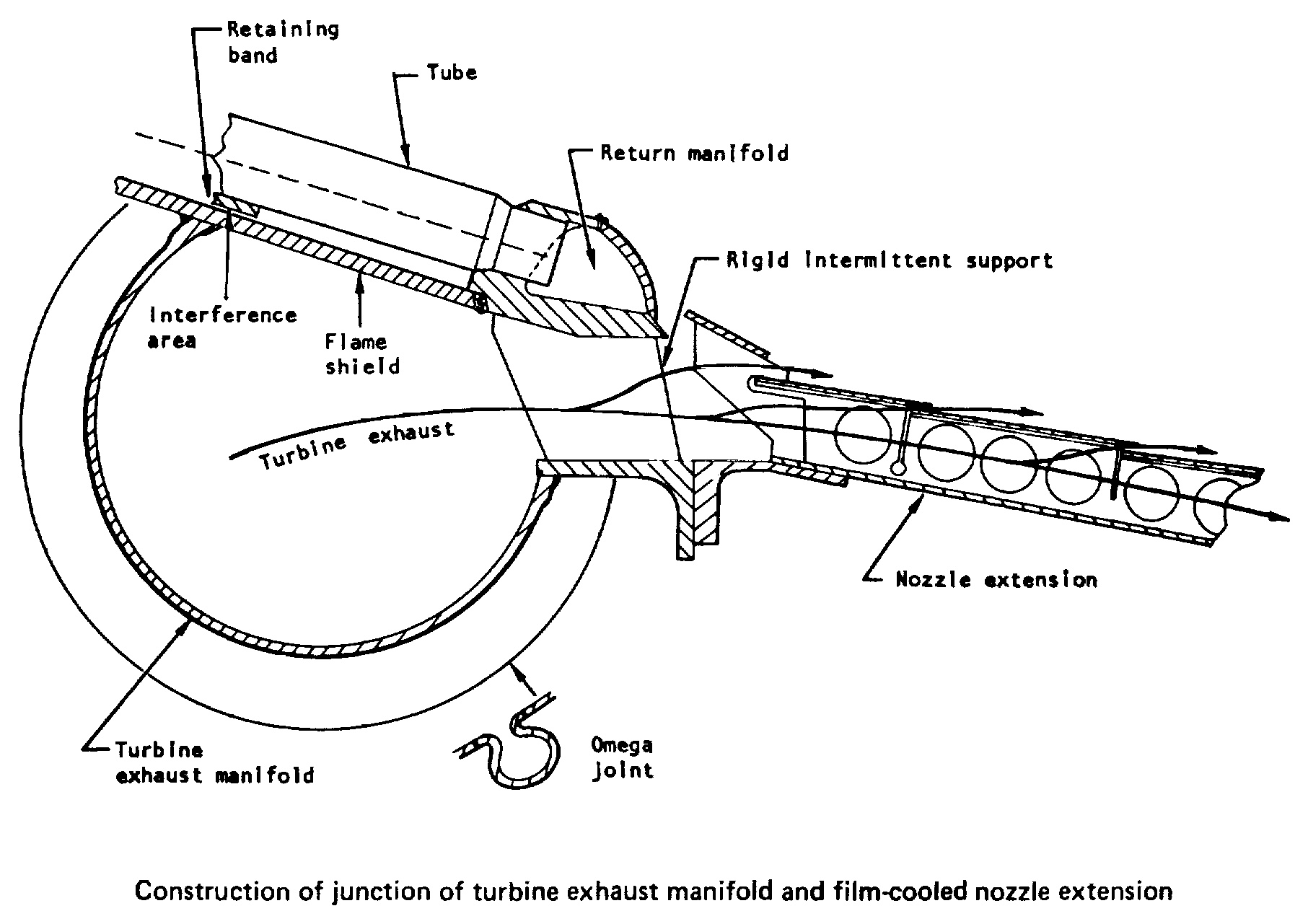

Nozze di figaro karl bohm. Rapid fabrication techniques for liquid rocket channel wall nozzles the functions of a regeneratively cooled nozzle are to 1 expand combustion gases to increase exhaust gas velocity while 2 maintaining adequate wall temperatures to prevent structural failure and 3 transfer heat from the hot gases to the coolant fluid to promote injector performance and stability. Modern actively cooled engine nozzles may be constructed using channel wall technology pioneered in russia. The rocket pumps and a combustion chamber generates high pressure a few hundred atmospheresthe nozzle turns the static high pressure.

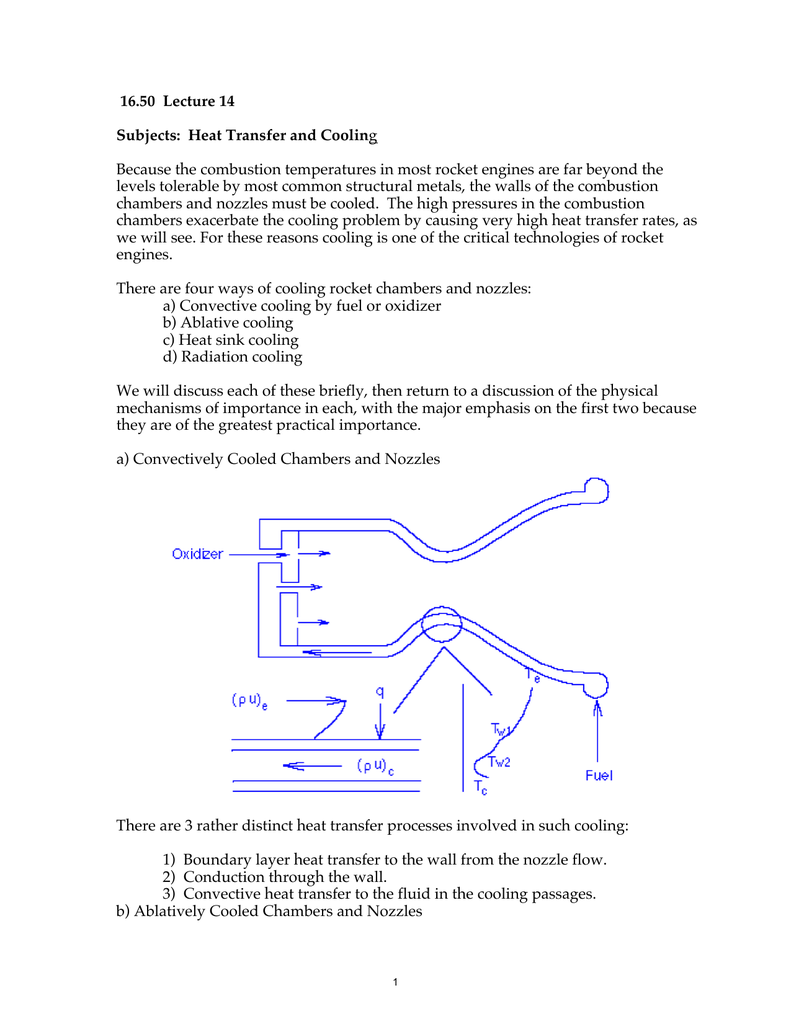

The conical nozzle was used often in early rocket applications because of its simplicity and ease of construction. Of these convection dominates and radiation tends to be important only for particle laden flows from solid propellant rockets. The throat size is chosen to choke the flow and set the mass flow rate through the system.

High gradient flow features like boundary layers on the rocket forebody and nozzle wall shear layers internal and external shocks plume impingement and interactions etc all add to the complexity. Most high power rocket nozzles are made from graphite. A rocket engine nozzle is a propelling nozzle usually of the de laval type used in a rocket engine to expand and accelerate the combustion gases produced by burning propellants so that the exhaust gases exit the nozzle at hypersonic velocities.

An overview of the rocket nozzles and flow field flow fields generated around rocket propulsion systems are complex and fascinating. Radiatively cooled nozzles such as the shuttle oms engines which have been cannibalized to use on the orion service module are formed of high temperature metals such as columbium or niobium. The wall contour is changed gradually enough to prevent oblique shocks.

A small angle produces greater thrust because it maximizes the axial component of exit velocity and. The flow in the throat is sonic which means the mach number is equal to one in the throat. The inner liner is under compression while the outer wall of the engine is under significant hoop stresses.

Graphite is an excellent material for nozzles for many reasons. Graphite rods come in many sizes and densities. In a cd rocket nozzle the hot exhaust leaves the combustion chamber and converges down to the minimum area or throat of the nozzle.

The cone gets its name from the fact that the walls diverge at a constant angle. To gain higher performance and shorter length engineers developed the bell shaped nozzle.