Steam Sparger Nozzle

Steam Sparger Nozzle, Indeed recently has been hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about

If the posting of this site is beneficial to our suport by spreading article posts of this site to social media marketing accounts which you have such as for example Facebook, Instagram and others or can also bookmark this blog page.

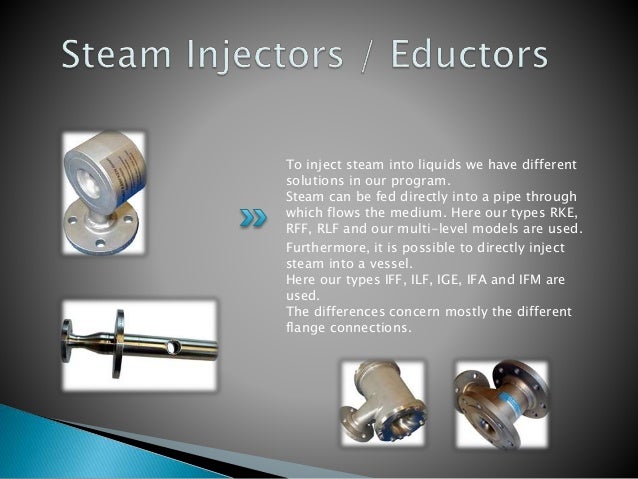

Sparger nozzles are classified as open tank heaters that entrain suction liquids using a high velocity steam issuing through a nozzle.

Nozzle mobil diesel. Direct contact high capacity steam heater. An eductor uses a nozzle to produce a high velocity fluid jet to entrain the liquid surrounding the eductor fluid can be either a gas or a liquid. The sparging factor improving the operating efficiency of flotation columns leach tanks and other processes that depend on the generation of fine gas bubbles in mineral flotation applications eriez flotation slamjet sparging systems promote the attachment and recovery of hydrophobic particles through the generation of a fine bubble.

Some of the heat contained in the steam will be lost to. No lubrication is required. Elmridge se series gas jet steam spargers are in tank direct contact heating devices used for directly injecting steam into vented process vessels.

Unless the steam injection system is designed so that all conditions are conducive to maximum heat transfer the steam bubbles may simply break the surface of the liquid and escape to the atmosphere. Multi nozzle water jet exhauster. Computer optimized flow paths enable the jrgjt tla to maintain a high pick up ratio the ratio of fluid entrained to the motive fluid while maximizing the hydraulic efficiency the ratio of hydraulic power at the outlet of the tla to the hydraulic power at the inlet to generate an optimum flow field from the greatest flow amplification.

The venturi design of these steam spargers provides superior injection performance due to the capability of the sparger to aggressively circulate tank contents reducing or eliminating thermal gradients. In equation 2111 the steam consumption rate is directly related to the heat requirement. Steam jet vacuum systems.

There are many advantages to using eductors for heating liquids in open vessels. Steam jet exhauster and compressor. Includes 53 different calculations.

Steam jet vacuum pump. Equations displayed for easy reference. Single nozzle water jet exhauster.

Sparger nozzle tla features. Agitation occurring in the diffuser breaks up the steam bubbles to give a quiet operation. Superior performance comes from a superior design.

Piping from a steam header directs the steam through a steam sparging nozzle that is located in the process fluid pipe. The fluid in the nozzle jet and the entrained liquid are forced through a diffuser where the high throughput velocity creates a turbulent flow. Factors influencing the h eat transfer rate.

Online calculator to quickly determine steam flow rate through an orifice.